skpyle

Full Access Member

- Joined

- May 15, 2021

- Posts

- 395

- Reaction score

- 1,025

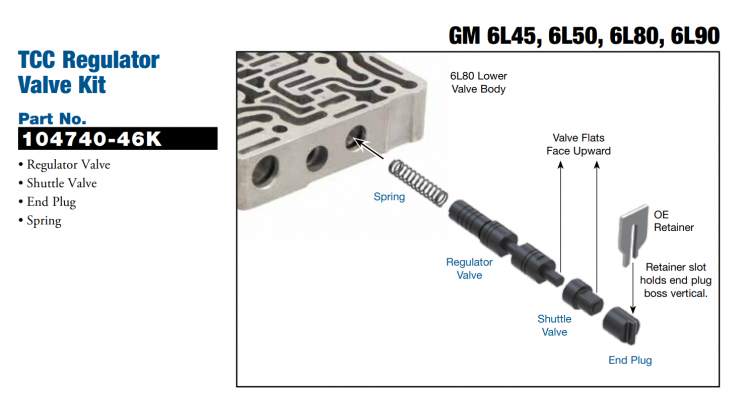

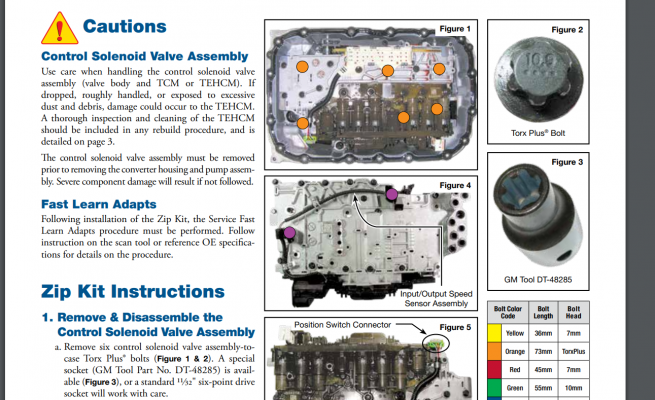

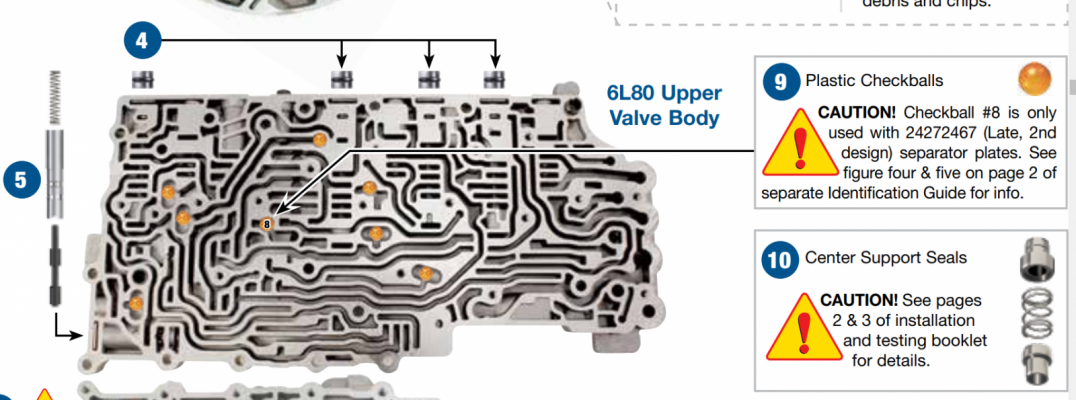

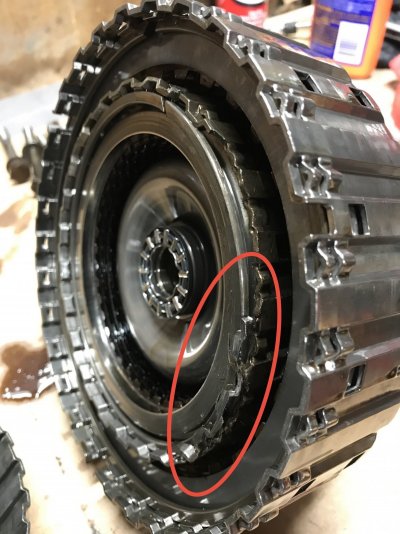

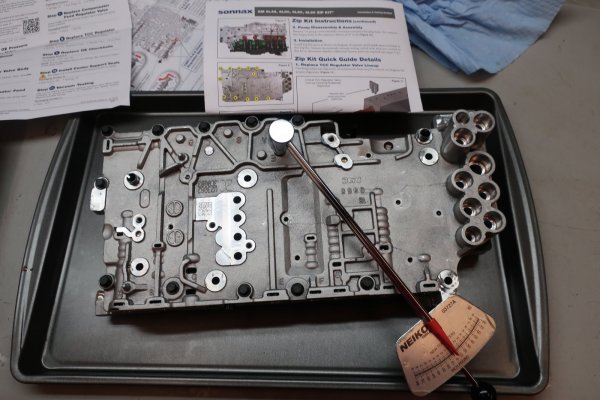

Next step was to install the Sonnax Actuator Feed Limit Valve. Again, valve held in place by a retainer. This time, the spring was on the outside of the valve, up against the retainer. Had to be careful to hold both 'sides' of the spring when pushing in to free the retainer. After I got my old valve out, I looked at the instructions, and went looking for the new valve. In the kit bag, I found the sleeve and the spring, but no valve. I had been gypped!!! No. I am just an idiot. The valve was inside the sleeve...

I installed the sleeve, being careful to orient the grooves to the inside, followed by the valve, with the spring seat to the outside, and then the spring. And then again fight the spring to install the retainer.

Actuator feed limit valve kit. Note: I removed the valve from the sleeve for the photo. Because I was dumb and couldn't find it earlier.

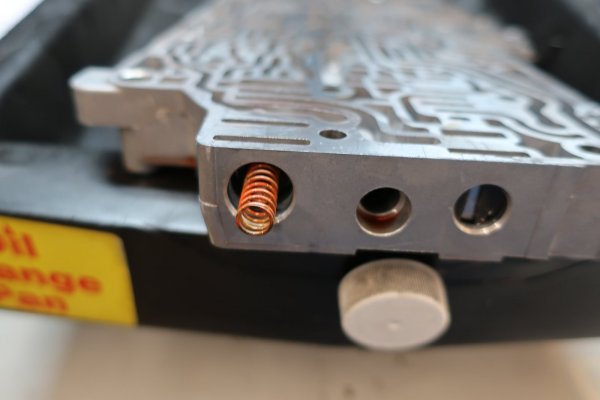

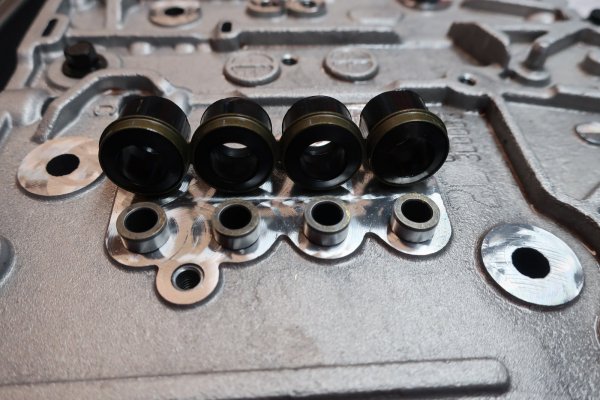

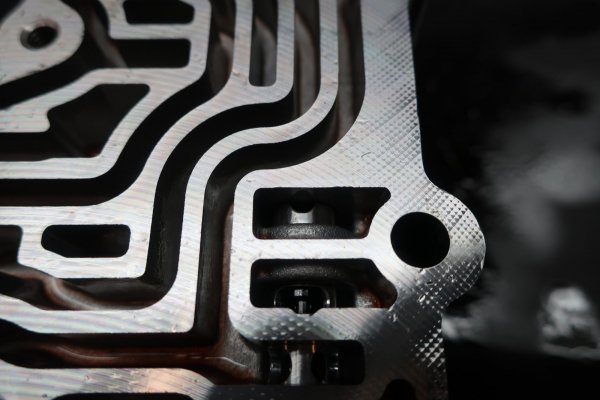

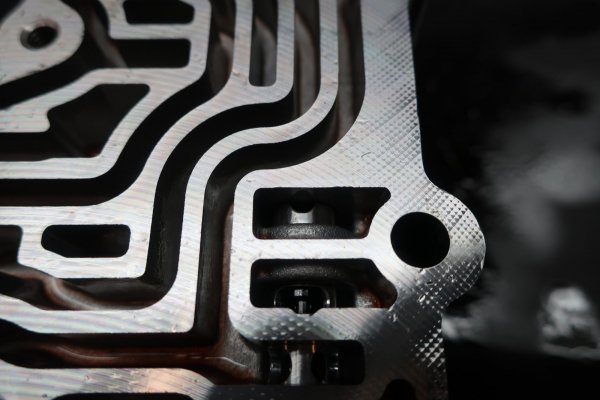

Actuator feed limit valve, spring peeking out behind the retainer.

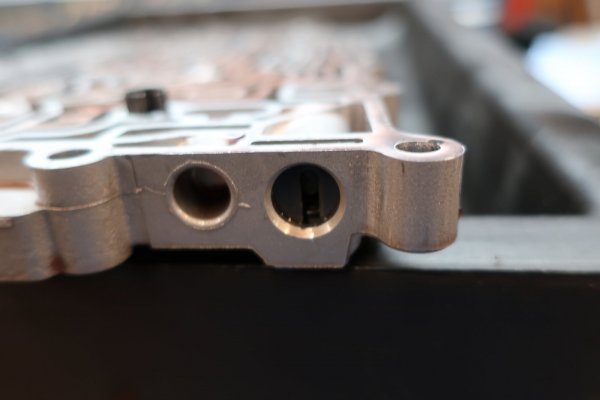

Spring and retainer.

OE actuator feed limit valve and spring.

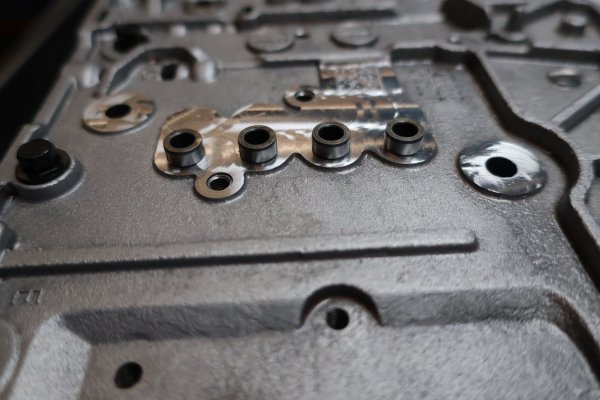

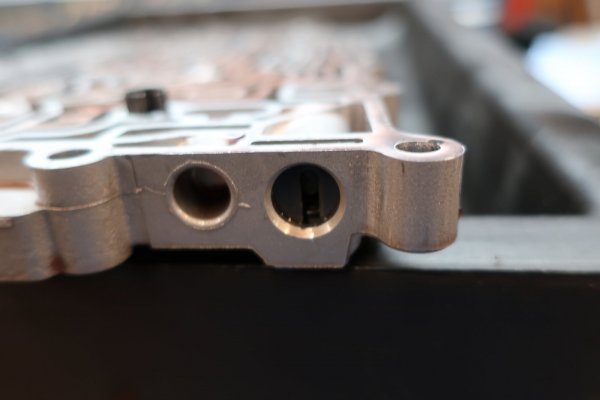

Looking at the sleeve through the valve body, you can see the one of the grooves at the top.

I installed the sleeve, being careful to orient the grooves to the inside, followed by the valve, with the spring seat to the outside, and then the spring. And then again fight the spring to install the retainer.

Actuator feed limit valve kit. Note: I removed the valve from the sleeve for the photo. Because I was dumb and couldn't find it earlier.

Actuator feed limit valve, spring peeking out behind the retainer.

Spring and retainer.

OE actuator feed limit valve and spring.

Looking at the sleeve through the valve body, you can see the one of the grooves at the top.