skpyle

Full Access Member

- Joined

- May 15, 2021

- Posts

- 395

- Reaction score

- 1,025

WARNING!!! This is NOT a straight bolt-on upgrade. Hand grinding is required on the spindle mounting ears and wheel spacers with longer lug studs will be REQUIRED! (At least they were for my stock 2013 Escalade ESV.)

Good Evening, Gentlemen!

As the title states, I am installing 6-piston GM/Brembo fixed calipers and 16" rotors on the front of my 2013 Escalade ESV with 154,8** miles on it. I am also overhauling the rear brakes to match.

Backstory: November 2021, at 125,0** miles, I went through the brakes on my Escalade. All four rotors turned, calipers sprayed off with brake cleaner, caliper brackets cleaned in parts washer, all new slider pins, bolts, boots, and pad slider plates. I also replaced the bleeder screws and installed pad drag reduction clips. I installed new Powerstop Z23 carbon fiber/ceramic brake pads at both ends.

All went well, and my Escalade had excellent brakes. They never felt lacking.

However...I can never leave well enough alone. I learned about the bolt-on PPV brake upgrade and couldn't get it out of my mind. I am rationalizing/justifying it as such: my Escalade weighs 5800lbs with my dumpster self in it, I like to drive fast on the highway, and I-85 can be a war zone at times.

So...better brakes is a good thing.

Here is the parts list for the front install:

Left caliper: GM Genuine 84793057

Right caliper: GM Genuine 84793058

Caliper mounting bolt (x4): GM Genuine 11546469 (NOTE: this is the matching part number for a 2021 PPV caliper)

Fender washer as spacer shim for calipers (x4): 3/8" ID, stainless steel, 0.060" and 0.040" thick, drilled out to 9/16"

Caliper banjo bolt (x2): GM Genuine 11569590 (NOTE: this is the same for 2013 stock caliper and 2021 PPV caliper)

Banjo bolt crush washer (10pk): GM Genuine 21012386

Rotor (x2): Power Stop AR82209EVC Evolution fully coated

Rotor retaining screw (x2): GM Genuine 11609271 (NOTE: this is the same for 2013 and 2021 rotor)

Pad set: Power Stop Z232407 Z23 Carbon Fiber-Ceramic

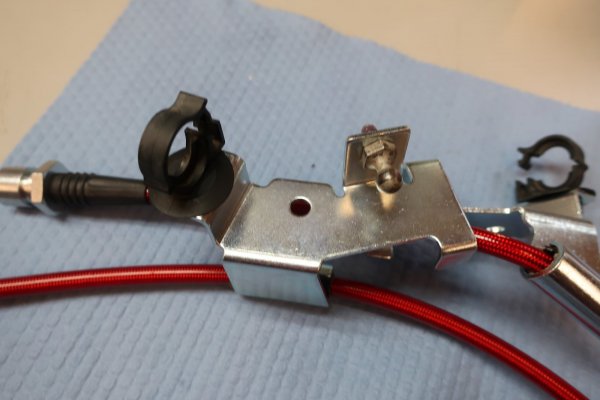

Braided steel brake hose set of 6: Power Stop BH00161

Massive honkin’ rotor!

Jumbo calipers and brake pads!

Braided steel front brake hoses with hardware and new GM banjo bolts.

6 piston goodness.

Good Evening, Gentlemen!

As the title states, I am installing 6-piston GM/Brembo fixed calipers and 16" rotors on the front of my 2013 Escalade ESV with 154,8** miles on it. I am also overhauling the rear brakes to match.

Backstory: November 2021, at 125,0** miles, I went through the brakes on my Escalade. All four rotors turned, calipers sprayed off with brake cleaner, caliper brackets cleaned in parts washer, all new slider pins, bolts, boots, and pad slider plates. I also replaced the bleeder screws and installed pad drag reduction clips. I installed new Powerstop Z23 carbon fiber/ceramic brake pads at both ends.

All went well, and my Escalade had excellent brakes. They never felt lacking.

However...I can never leave well enough alone. I learned about the bolt-on PPV brake upgrade and couldn't get it out of my mind. I am rationalizing/justifying it as such: my Escalade weighs 5800lbs with my dumpster self in it, I like to drive fast on the highway, and I-85 can be a war zone at times.

So...better brakes is a good thing.

Here is the parts list for the front install:

Left caliper: GM Genuine 84793057

Right caliper: GM Genuine 84793058

Caliper mounting bolt (x4): GM Genuine 11546469 (NOTE: this is the matching part number for a 2021 PPV caliper)

Fender washer as spacer shim for calipers (x4): 3/8" ID, stainless steel, 0.060" and 0.040" thick, drilled out to 9/16"

Caliper banjo bolt (x2): GM Genuine 11569590 (NOTE: this is the same for 2013 stock caliper and 2021 PPV caliper)

Banjo bolt crush washer (10pk): GM Genuine 21012386

Rotor (x2): Power Stop AR82209EVC Evolution fully coated

Rotor retaining screw (x2): GM Genuine 11609271 (NOTE: this is the same for 2013 and 2021 rotor)

Pad set: Power Stop Z232407 Z23 Carbon Fiber-Ceramic

Braided steel brake hose set of 6: Power Stop BH00161

Massive honkin’ rotor!

Jumbo calipers and brake pads!

Braided steel front brake hoses with hardware and new GM banjo bolts.

6 piston goodness.

Last edited: