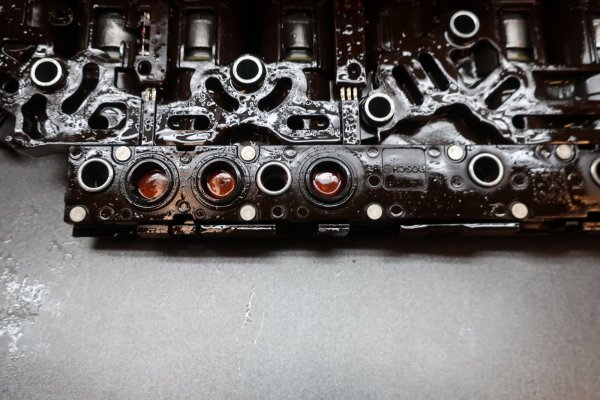

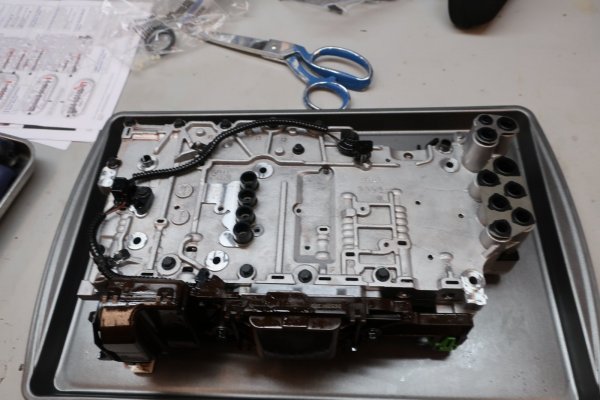

Installing the valve body was a real treat...

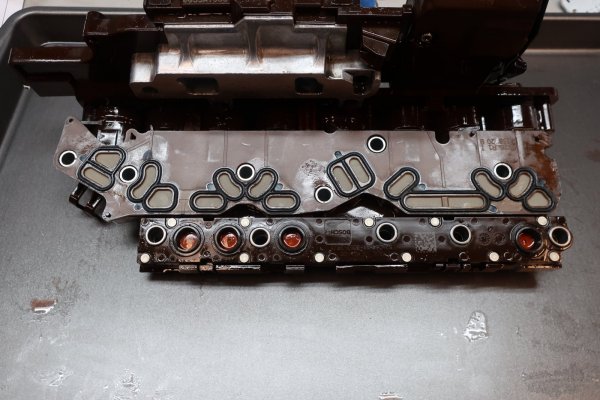

I was concerned with aligning the bushings for the center seal stack on the valve body with the seal stack installed in the transmission case. Because I had to install the back of the valve body first to engage the electrical connector, then tilt the front of the valve body up. Also, don't forget to make sure the black plastic plunger on the position indicator switch lines up correctly the manual shift shaft lever. I got it the first try, though it was a bit nerve wracking. There is no way to see the seal to see if it went in. I just went by feel. IE the valve body felt flat against the transmission casing with no rocking. I started all six EP10 Torx Plus bolts and tightened them hand tight.

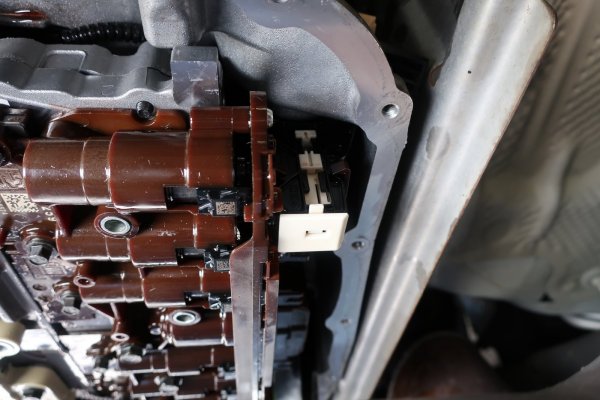

And then remembered the white latch for the electrical connector.

And it wouldn't latch. I tried pushing a touch harder. Bad idea, things started flexing.

I tried manipulating the latch back and forth. Side to side. Nothing.

I loosened the valve body mounting bolts and gently pushed the valve body towards the electrical connector.

Nope.

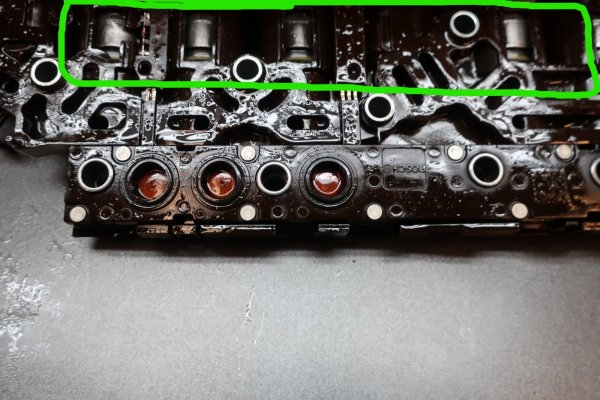

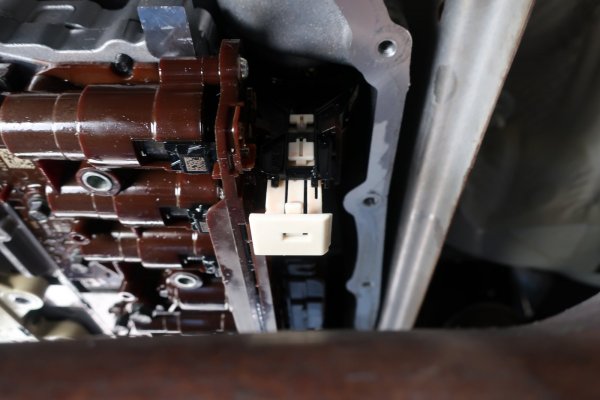

Electrical connector latch. Not latched.

So...I pulled the valve body back out. I did find that none of the center seals were deformed, so I did get it right on install.

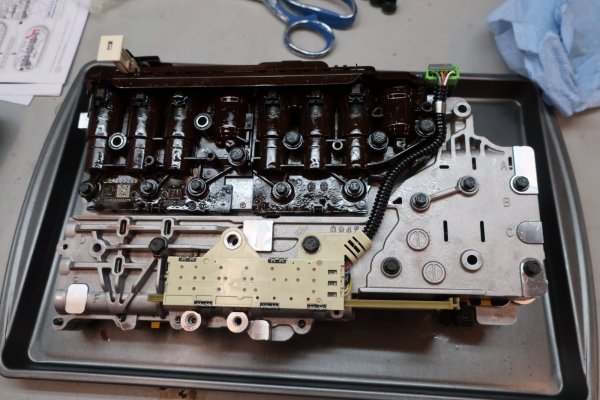

Back on the work bench, I looked at the latch. I looked at the electrical connector on the TECHM. And found nothing wrong. I tried pushing the latch. It would not go.

I performed google-fu for valve body electrical connector. I watched videos. Only one had anything to do with the electrical connector, and it was for the plug outside the case. Which wasn't my problem. (Ominous foreboding music...)

Looking closer, there are two little metal 'fingers' at the bottom of the latch. I gently pushed the fingers towards the TECHM with a pick and pushed down on the latch.

CLICK. It latched.

This told me the electrical connector wasn't seated properly.

Hmmm...if the valve body can't move any closer to the connector (because of the center seal stack and the mounting bolts), then maybe the case electrical connector isn't right?

That thought scared the bejezzus out of me. I really don't like damaging things on my new toys. Especially ones I need to drive daily.

Back under the Escalade, I stuck my head up behind the transmission to look at the electrical connector on the outside of the case. I gently pulled on the cable to see if it was tight. And the whole thing came off and out of the transmission. And I deposited ***** matter into my undergarments.

After learning to breathe again, I remembered the useless youtube video I watched on the electrical connector that wasn't my problem. It discussed how the outer electrical connector was a twist lock type of connector. OK...

I reinstalled the valve body. I then gently pushed the electrical connector back into the transmission case and turned as I went. I turned and then fell into position. I gave it a little push and the off-white latch on the connector latched into the transmission case.

Back at the valve body, I pushed on the electrical connector white latch. It latched.

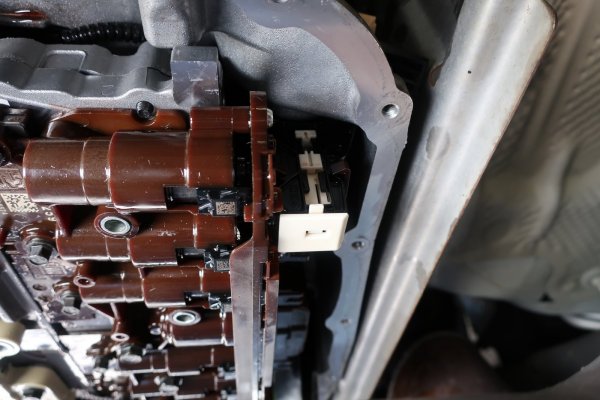

Electrical connector at the back of the transmission case. Note the off-white latch and the black lever sticking out to the right...

View of the electrical connector on the TECHM through the port in the transmission case from the outside. If you zoom in, you can just see the spiral grooves in the connector locking sleeve inside the port.

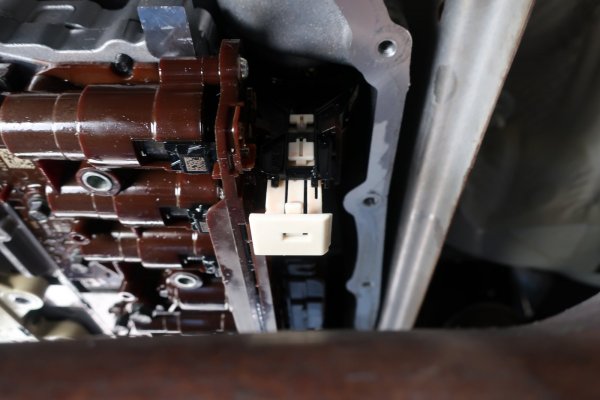

Electrical connector latch. Latched.

Finally. The valve body was completely reinstalled.