if the key is on and you put some weight on the rear like have a couple adults stand on the rear bumper so you are adding some noticeable weight, then the pump should kick on and level the vehicle, then when you step off it should then release some air and re-level the vehicle within a few seconds. you have to listen for the air release it's not a noticeable pssst sound its more of a exhale sound. This is why it is called "auto-level"

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Autoride suspension help

- Thread starter BH1989

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

George B

¯\_(ツ)_/¯

What was the root issue for you?if you monitor the pump with a tech2 you can see the pressure drop right before the pump kicks on and if you are near the pump you should hear it exhale then kick on, if the vehicle is unloaded it should inflate to around 20-25 psi. if you cycle the key again quickly it may then release some air inflate and to around 30-35, if you wait a bit and do it again instead of quickly cycling the key it should stay at around 20-25 psi. I have tested the heck out of mine when I was trying to figure what the hell was wrong, one stupid pump would give bad readings with air reading anywhere from 0-180psi (had a bad sensor inside) and it did not inflate each time like it should, the next pump leaked air, finally on my 3rd pump it works properly.

With the original system the shocks were leaking and the pump was not turning on each time.What was the root issue for you?

replaced the shocks and pump with all arnott, it worked fine for a while (a few months) and then the pump started not coming on each time.

determined arnott pump air pressure sensor was bad, replaced the pump with another arnott

that pump worked for a couple months and then began to leak, determined the leak was from the relief valve

replaced the pump with a Dorman and everything has been fine for a little over a year or so

holds air and pump works each time, air increases and releases depending on load.

willfalcon

TYF Newbie

- Joined

- Jul 4, 2020

- Posts

- 16

- Reaction score

- 10

Since you did get the compressor to kick on after manually relieving pressure, this probably doesn't mean anything, but just for the general information of anyone else reading... when I did my system last year I got Arnott shocks and a replacement compressor from Suncore, and once everything was hooked up, it wouldn't come on at all. Did all those electrical tests, all was checking out right, got super frustrated, but finally figured out that the main electrical harness was just really hard to get plugged in all the way.

George B

¯\_(ツ)_/¯

@BH1989 I hope you don't mind if I hijack but I see no reason to start another thread for this.

I am having rear suspension issues as well. I noted my compressor running more than normal and that the suspension rides lower than normal while towing.

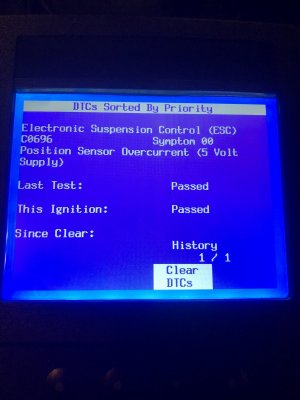

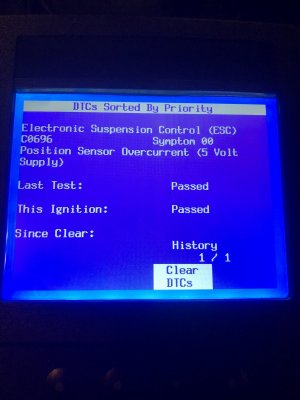

I connected my Tech2 today and took a look at the suspension. First thing I noticed was a C0696 code that comes back immediately after I clear it. I found this TSB for the code but I don't have C0711.

The suspension pressure was at around 22 psi after the compressor self test while sitting level in the shop.

I did a compressor test and was able to pump the pressure up to about 80 psi. I did a leak check on the rear bags and found they do foam a bit and will likely need to be replaced but I don’t believe they leak at a rate to cause the issue I am having.

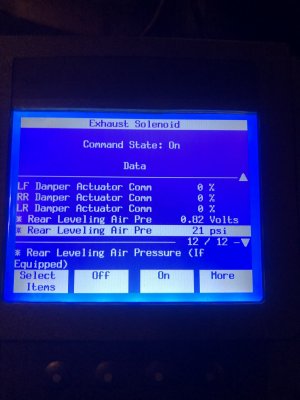

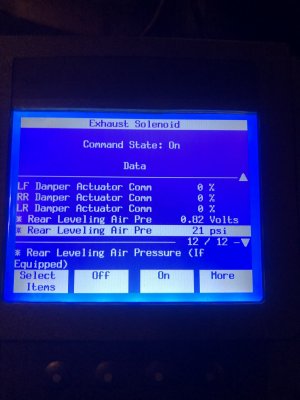

Next I did a test of the relief valve. This is where it gets weird. When I toggled the valve on my pressure dropped slowly but I could ‘t hear it exhaust. I did have the truck running so perhaps that was why. I have heard it before. It took a while but would not drop down below the 22 psi.

Next I decided to do the ALC calibration. So it went through it’s recalibration and then the dic indicated a SERVICE SUSPENSION warning and each time I would clear that C0696 code it would go out and come right back with the code.

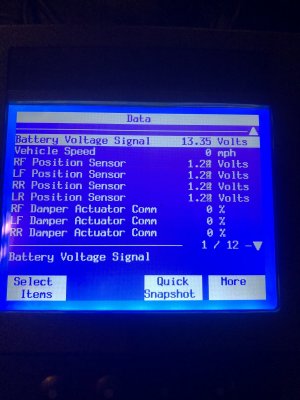

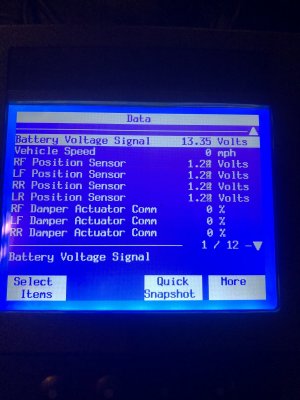

At first the front and rear ride sensors were reading different values but after the recalibration they all read the same. I assume this is normal and a result of the recalibration.

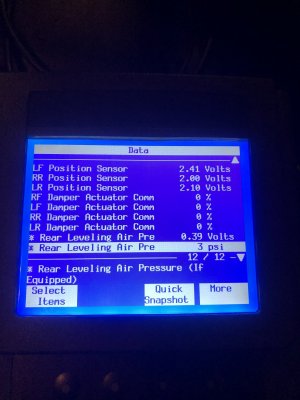

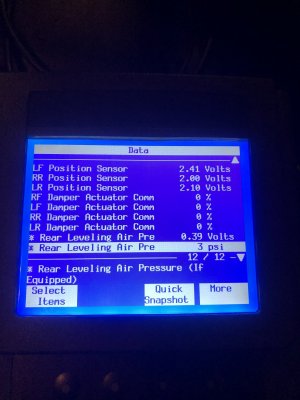

Now after the recalibration and a few compressor runs I noticed the system pressure was way up over 180psi. I attempted to relieve the pressure with the solenoid but it didn’t seem to work. Just sitting looking at the data after that resulted in this video of it jumping all over. I pulled the right rear line and it went down to about 20 psi so I pulled the left one and it settled down to 3 psi. And I noted the values of the sensors were different again.

@Doubeleive

Some pics to show what I was seeing:

View attachment 271557

I am having rear suspension issues as well. I noted my compressor running more than normal and that the suspension rides lower than normal while towing.

I connected my Tech2 today and took a look at the suspension. First thing I noticed was a C0696 code that comes back immediately after I clear it. I found this TSB for the code but I don't have C0711.

The suspension pressure was at around 22 psi after the compressor self test while sitting level in the shop.

I did a compressor test and was able to pump the pressure up to about 80 psi. I did a leak check on the rear bags and found they do foam a bit and will likely need to be replaced but I don’t believe they leak at a rate to cause the issue I am having.

Next I did a test of the relief valve. This is where it gets weird. When I toggled the valve on my pressure dropped slowly but I could ‘t hear it exhaust. I did have the truck running so perhaps that was why. I have heard it before. It took a while but would not drop down below the 22 psi.

Next I decided to do the ALC calibration. So it went through it’s recalibration and then the dic indicated a SERVICE SUSPENSION warning and each time I would clear that C0696 code it would go out and come right back with the code.

At first the front and rear ride sensors were reading different values but after the recalibration they all read the same. I assume this is normal and a result of the recalibration.

Now after the recalibration and a few compressor runs I noticed the system pressure was way up over 180psi. I attempted to relieve the pressure with the solenoid but it didn’t seem to work. Just sitting looking at the data after that resulted in this video of it jumping all over. I pulled the right rear line and it went down to about 20 psi so I pulled the left one and it settled down to 3 psi. And I noted the values of the sensors were different again.

@Doubeleive

Some pics to show what I was seeing:

View attachment 271557

So your exhaust solenoid isn’t working? Either way that TSB shows the pressure sensor not working due to the wiring being shorted. Could be that’s your problem, maybe the system doesn’t know what the pressure is. I guess it’s time to have a look at it.@BH1989 I hope you don't mind if I hijack but I see no reason to start another thread for this.

I am having rear suspension issues as well. I noted my compressor running more than normal and that the suspension rides lower than normal while towing.

I connected my Tech2 today and took a look at the suspension. First thing I noticed was a C0696 code that comes back immediately after I clear it. I found this TSB for the code but I don't have C0711.

The suspension pressure was at around 22 psi after the compressor self test while sitting level in the shop.

I did a compressor test and was able to pump the pressure up to about 80 psi. I did a leak check on the rear bags and found they do foam a bit and will likely need to be replaced but I don’t believe they leak at a rate to cause the issue I am having.

Next I did a test of the relief valve. This is where it gets weird. When I toggled the valve on my pressure dropped slowly but I could ‘t hear it exhaust. I did have the truck running so perhaps that was why. I have heard it before. It took a while but would not drop down below the 22 psi.

Next I decided to do the ALC calibration. So it went through it’s recalibration and then the dic indicated a SERVICE SUSPENSION warning and each time I would clear that C0696 code it would go out and come right back with the code.

At first the front and rear ride sensors were reading different values but after the recalibration they all read the same. I assume this is normal and a result of the recalibration.

Now after the recalibration and a few compressor runs I noticed the system pressure was way up over 180psi. I attempted to relieve the pressure with the solenoid but it didn’t seem to work. Just sitting looking at the data after that resulted in this video of it jumping all over. I pulled the right rear line and it went down to about 20 psi so I pulled the left one and it settled down to 3 psi. And I noted the values of the sensors were different again.

@Doubeleive

Some pics to show what I was seeing:

View attachment 271557 View attachment 271558 View attachment 271559 View attachment 271560 View attachment 271561

Last edited:

George B

¯\_(ツ)_/¯

It may or may not be. I don’t know how fast the pressure should drop. I also don’t think the pressure sensor is working as it should.So your exhaust solenoid isn’t working?

I had pretty much the same problem with a arnott pump I replaced it and the problem went away, how any miles on your truck?@BH1989 I hope you don't mind if I hijack but I see no reason to start another thread for this.

I am having rear suspension issues as well. I noted my compressor running more than normal and that the suspension rides lower than normal while towing.

I connected my Tech2 today and took a look at the suspension. First thing I noticed was a C0696 code that comes back immediately after I clear it. I found this TSB for the code but I don't have C0711.

The suspension pressure was at around 22 psi after the compressor self test while sitting level in the shop.

I did a compressor test and was able to pump the pressure up to about 80 psi. I did a leak check on the rear bags and found they do foam a bit and will likely need to be replaced but I don’t believe they leak at a rate to cause the issue I am having.

Next I did a test of the relief valve. This is where it gets weird. When I toggled the valve on my pressure dropped slowly but I could ‘t hear it exhaust. I did have the truck running so perhaps that was why. I have heard it before. It took a while but would not drop down below the 22 psi.

Next I decided to do the ALC calibration. So it went through it’s recalibration and then the dic indicated a SERVICE SUSPENSION warning and each time I would clear that C0696 code it would go out and come right back with the code.

At first the front and rear ride sensors were reading different values but after the recalibration they all read the same. I assume this is normal and a result of the recalibration.

Now after the recalibration and a few compressor runs I noticed the system pressure was way up over 180psi. I attempted to relieve the pressure with the solenoid but it didn’t seem to work. Just sitting looking at the data after that resulted in this video of it jumping all over. I pulled the right rear line and it went down to about 20 psi so I pulled the left one and it settled down to 3 psi. And I noted the values of the sensors were different again.

@Doubeleive

Some pics to show what I was seeing:

View attachment 271557 View attachment 271558 View attachment 271559 View attachment 271560 View attachment 271561 View attachment 271567

George B

¯\_(ツ)_/¯

Just shy of 70kI had pretty much the same problem with a arnott pump I replaced it and the problem went away, how any miles on your truck?

George B

¯\_(ツ)_/¯

After thinking about this more I don’t understand why I can’t clear that C0696 code if all the sensors are reading back ok temporarily. The four position sensors and the pressure sensor are what feeds that and on my last screen shot you can see them all reading within range. I still suspect that pressure sensor.@BH1989 I hope you don't mind if I hijack but I see no reason to start another thread for this.

I am having rear suspension issues as well. I noted my compressor running more than normal and that the suspension rides lower than normal while towing.

I connected my Tech2 today and took a look at the suspension. First thing I noticed was a C0696 code that comes back immediately after I clear it. I found this TSB for the code but I don't have C0711.

The suspension pressure was at around 22 psi after the compressor self test while sitting level in the shop.

I did a compressor test and was able to pump the pressure up to about 80 psi. I did a leak check on the rear bags and found they do foam a bit and will likely need to be replaced but I don’t believe they leak at a rate to cause the issue I am having.

Next I did a test of the relief valve. This is where it gets weird. When I toggled the valve on my pressure dropped slowly but I could ‘t hear it exhaust. I did have the truck running so perhaps that was why. I have heard it before. It took a while but would not drop down below the 22 psi.

Next I decided to do the ALC calibration. So it went through it’s recalibration and then the dic indicated a SERVICE SUSPENSION warning and each time I would clear that C0696 code it would go out and come right back with the code.

At first the front and rear ride sensors were reading different values but after the recalibration they all read the same. I assume this is normal and a result of the recalibration.

Now after the recalibration and a few compressor runs I noticed the system pressure was way up over 180psi. I attempted to relieve the pressure with the solenoid but it didn’t seem to work. Just sitting looking at the data after that resulted in this video of it jumping all over. I pulled the right rear line and it went down to about 20 psi so I pulled the left one and it settled down to 3 psi. And I noted the values of the sensors were different again.

@Doubeleive

Some pics to show what I was seeing:

View attachment 271557 View attachment 271558 View attachment 271559 View attachment 271560 View attachment 271561 View attachment 271567

Similar threads

- Replies

- 1

- Views

- 527

- Replies

- 9

- Views

- 874

- Replies

- 3

- Views

- 1K

- Replies

- 1

- Views

- 125