Here is the latest email from Gruven...

Hi Ken,

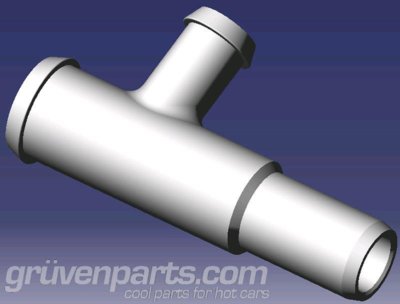

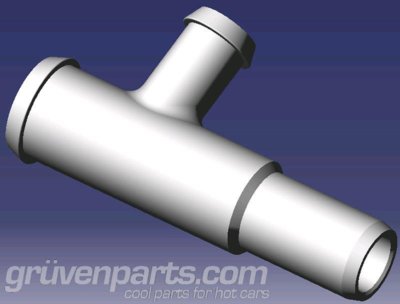

Attached is a CAD screen shot of the GruvenParts billet heater core tee. Note that the smaller ½” hard line connector had to move away from center line of the tee by about 1” to do this. This was necessary to account for the weld bead so we could make sure to have enough tube to clamp the hose on. The larger ¾” hard line connection is at the factory location so that line would not need to move much if any.

This tee will be CNC machined from 6061-T651 aircraft grade aluminum bar and TIG welded by our licensed A&P mechanics in our Atlanta machining center. We will then pressure check each fitting to ensure the integrity of the welds. Each tee will include the short pieces of automotive grade heater hose in ½” and ¾” inner diameter as well as 4 high quality stainless steel worm screw clamps per SAE J1508 so the customer will have all required to install.

Pricing - $59.99 ea

We need 10 pre-orders so just have people email me directly if they want them, it won’t take long to make this (1-2 weeks once we gather interest).

Things I need from you :

- Can you verify the ½” hard line could move away from tee center by 1” without binding, kinking or hitting the cowl structure ?

- What is the OEM part number and what all years/makes/models do these tees go into ? We can research other forums and see if we can gain additional interest to get this moving.

Thanks,

Paul

www.GruvenParts.com

https://www.facebook.com/GruvenParts/