on going problems:

took a look at fuel crap, ive been running it full time to keep it primed and not having it continuously turning on and off. cheap relay bases lost the control wire...found that and fixed it but pump just wont turn on, even just jumping it from the battery. think its done

engine temps:

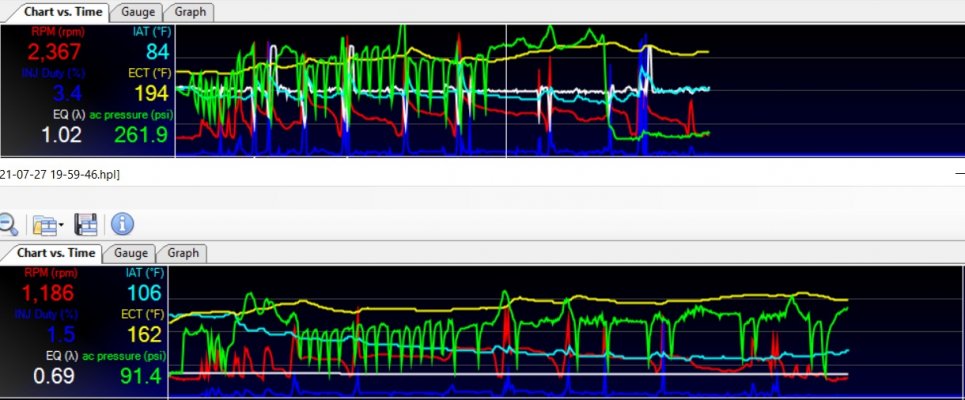

without the ac on it seems to do great, with the chiller i need to run ac most of the time though - idling it looks like it will maintain about 185* with the ac on which is fine...but cruising after like 20-30mins it climbs up to about 220 is as high as ive let it go. i jumped out the fans to make sure they were working right, spinning the right way, lo/hi was correct, set the on/offs differently. also cruising the ac compressor is turning higher rpm also - which is going to add to the pressure so i may need to check pressures with it rpm steady and above idle speed 1500-2000rpm or something

im going to go back to the ac pressures, in the first 30mins of driving the high side pressure stays good 240-250psi after that the pressure jumps up to 280psi+ and temp starts to climb - i dont know if it gets heat soaked or dryer/accumulator allows more to circulate but i think i need to run it and heat soak it into that range and then troubleshoot.

it sucks cause my gauge ports hi side is after the condenser, not between the compressor and condenser where i think it should be. low side on suction where it needs to be. the pressure sensor the truck sees is between the compressor and condenser, so i need to hook gauge up and look at that sensor. over the weekend while i was trouble shooting about 90* outside, out the vents it was blowing about 55* pressure on the hi side was a little high so i pulled some refrigerant out, temp dropped to about 52 at the vent, pulled a little more and it went back up to 55 - but i may not have waiting long enough for the dryer/accumulator to allow more t ocirculate, gave it a quick shot and dropped back down to 52ish. but pressure was still about 25psi too high on the hi side, ive read this could cause the condenser to not work as efficiently and put off a lot of heat (which it would be expelling right onto the radiator). i may try and get the hi side pressure down to where it should be (250psi) from 275-285psi its at now, and then add take away to get the coldest vent temp.

havent really messed with the belt - i just pulled the washer out from behind the tensioner pulley and threw a new belt on it, you can see where its rubber in the tensioner i would need to move it closer to the block to make it quit doing that, but it only happens high rpm bracket flexing or something i dont know. may see if i can find a pulley with some higher sides to keep the belt between it

i will probably flush the cooling system and install some fresh 50/50...ive been changing up steam vent/overflow hoses and crap so much, and bit of the copper spray made it into there kinda copper cloudy looking

havent noticed anything leaking, but i also havent lifted it back up and looked very close, just no drip spots under it