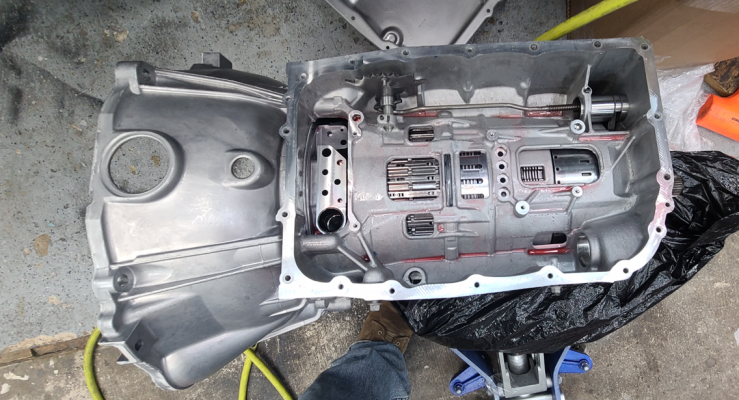

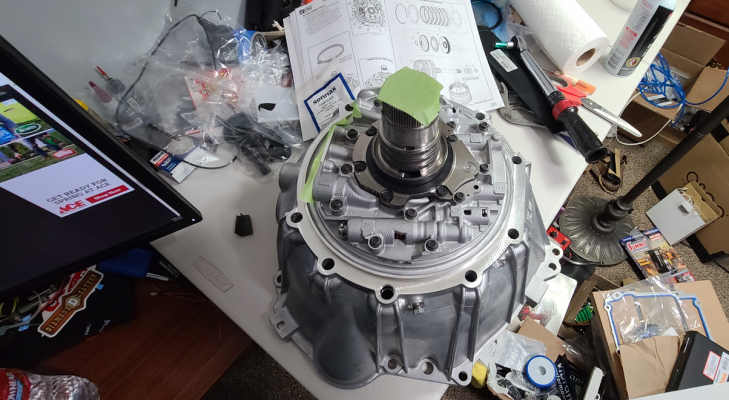

I did this with some general tools, hardest part was pressing the pistons back in place.

I used a cheap amazon tranmission press modified to have a larger base and screwed down to a table...

I really went heavy on the assembly Gel due to fears of tearing a piston seal

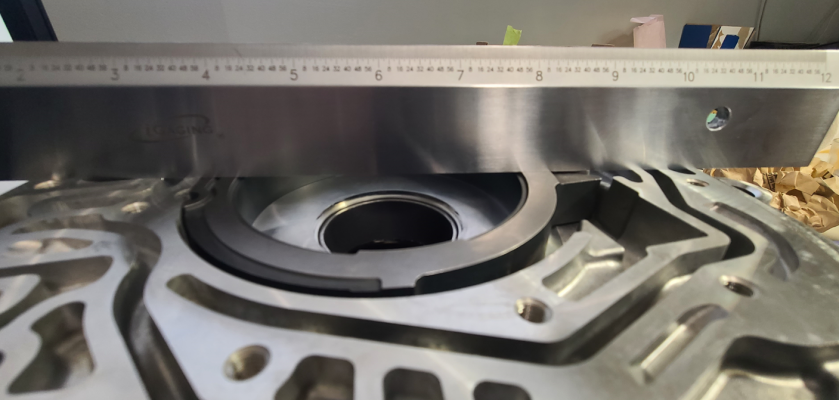

For bushings I used a generic bushing install kit, lots of pictures and measurements to ensure I installed the bushings at the exact same depth.

The best installed bushings were ones that I needed to make up some missing space for the inside of the bushing with electrical tape.

Used super 33 for the smaller spaces, and super 88 when slightly more space was needed.

For some reason those bushings were the best fitting.

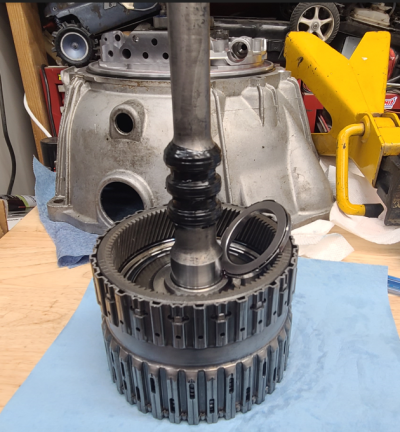

The one Official 6l80 tool I bought was for the giant snap ring.

As a novice w/o all the correct tools, the trick is to go real slow and take your time.

Blue print the fk out of it, detail everything.

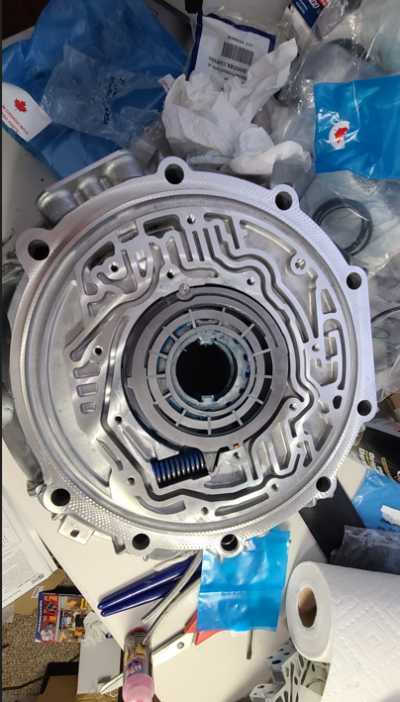

And I had fun with this.

Last/first transmission was a 700R4 on my C4 vette, I replaced all of the internals, only the valve body, output shaft, and the transmission case is orignal.

the 6l80 was much better experience.