Just Fishing

Can't fix stupid

Do you have any pics of this? Perhaps I’m misunderstanding but are you saying you put electrical tape on the inside diameter of a bushing?

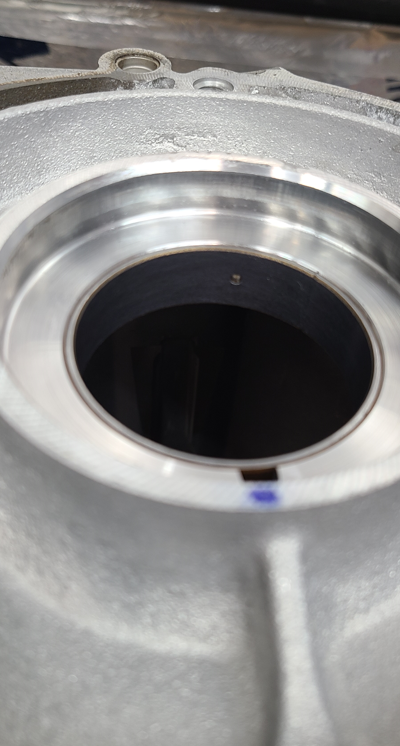

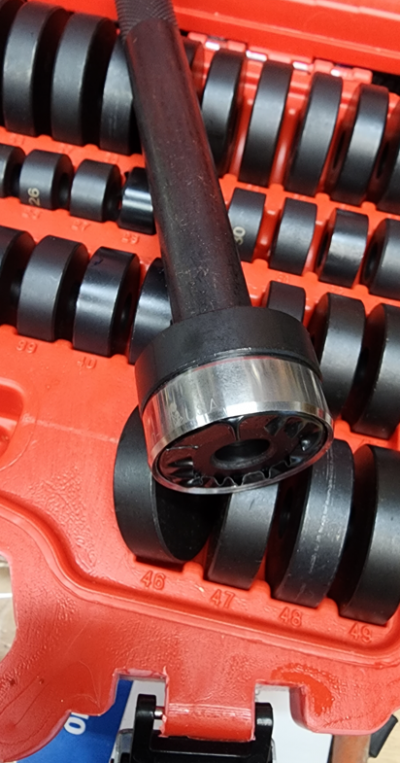

Here we go,

I had to go out to my bushing set, i just happened to have a spare bushing + a few of the drivers that still had the electrical tape installed.

I hope this makes sense.

Tape used to make the bushing driver fit the bushing tighter, preventing it from deforming when driving in.

ETA: of course the tape does not stay with the bushing in any way.