Jason in DLH

Cheeseburger and Fries

So after attempting to drill out broken and rusted bolts on my old car with several good bits breaking I did a bit of research and concluded the following:

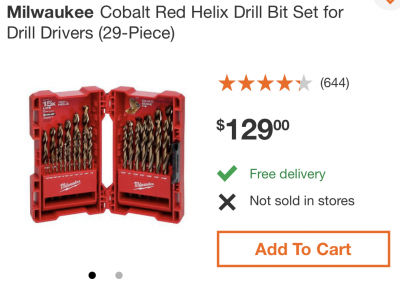

1. Use Cobalt drill bits. Start small and progressively get larger. This set is what I use with fantastic results...

I would rate this set 5 stars as I’ve used them numerous times without issue.

2. Use cutting oil. I use this with great results...

3. Use slow speeds and have patience!

Note: if you’ve never used Cobalt bits, careful when handling as they are extremely sharp!

Hope this helps someone!

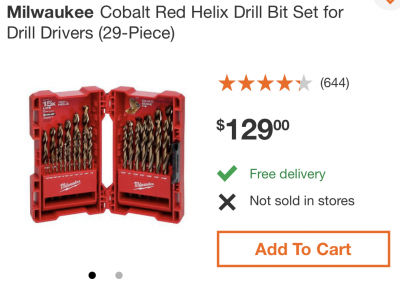

1. Use Cobalt drill bits. Start small and progressively get larger. This set is what I use with fantastic results...

I would rate this set 5 stars as I’ve used them numerous times without issue.

2. Use cutting oil. I use this with great results...

3. Use slow speeds and have patience!

Note: if you’ve never used Cobalt bits, careful when handling as they are extremely sharp!

Hope this helps someone!