Hi all,

I've inherited my father-in-law's 1999 Tahoe a couple of years ago and I'm finally trying to sort out the A/C (which he was in the process of trying to revive when he passed away).

I, unfortunately, didn't get to talk with him about it before he passed.

I knew that he had replaced the compressor but when I inherited it, the system was empty.

I've flushed all the flushable lines and replaced orifice tubes and the rear expansion valve and the accumulator/dryer.

The system held shop air fine at about 60 psi.

I vacuumed it down and it's held vacuum fine for the past week or so.

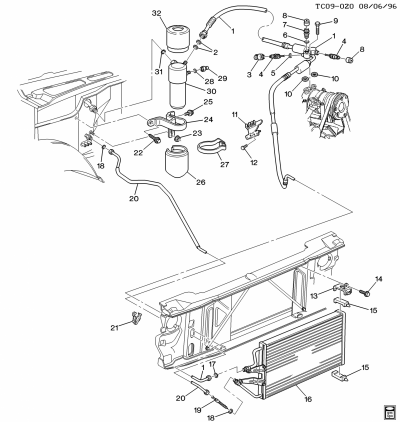

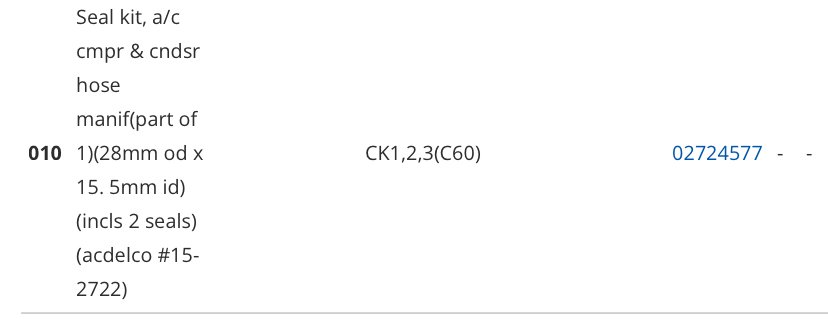

I went to charge it up today and was immeadiately met with a HUGE leak at the high side connection between the compressor and the muffler line that runs to the condenser.

At this point, I think I either don't have the correct sealing washer or a spacer or something, or that the replacement compressor isn't compatible with the OEM line connector block.

Can anyone advise what I should be looking for/verifying/changing?

Thanks for the advice

-Bob

I've inherited my father-in-law's 1999 Tahoe a couple of years ago and I'm finally trying to sort out the A/C (which he was in the process of trying to revive when he passed away).

I, unfortunately, didn't get to talk with him about it before he passed.

I knew that he had replaced the compressor but when I inherited it, the system was empty.

I've flushed all the flushable lines and replaced orifice tubes and the rear expansion valve and the accumulator/dryer.

The system held shop air fine at about 60 psi.

I vacuumed it down and it's held vacuum fine for the past week or so.

I went to charge it up today and was immeadiately met with a HUGE leak at the high side connection between the compressor and the muffler line that runs to the condenser.

At this point, I think I either don't have the correct sealing washer or a spacer or something, or that the replacement compressor isn't compatible with the OEM line connector block.

Can anyone advise what I should be looking for/verifying/changing?

Thanks for the advice

-Bob