Buggdave

Full Access Member

I use my Denali for towing a travel trailer, about 5,000 lbs, though the mountains at least monthly. I regularly reach elevations at 10,000 ft here in Utah. Over the summer I traveled into Wyoming and was at 11,500 ft. When I reach these elevations, i was having trouble keeping the engine cool on some of the uphill long pulls. I researched and decided to add a Mishimoto radiator. This thing is a beast.

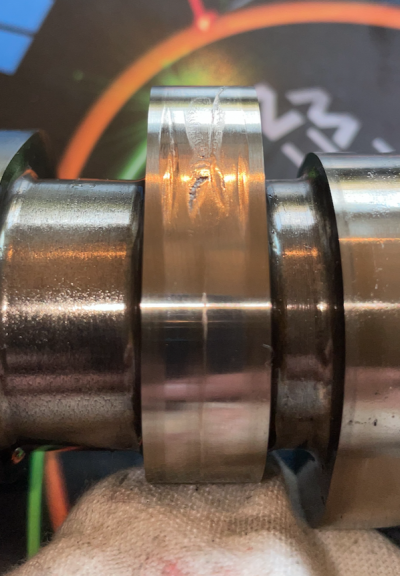

My research had shown that with a few of the other 3 row aluminum radiators did not have the overflow connection design correctly. They did not have a flow reducing bushing which causes the engine to have a hard time warming up. The solutions to fix this was simple, put a washer in the overflow line at the radiator, but i happened on an open box Mishimoto radiator from Amazon that was about the same price as the no-name radiators, so it was a no brainer. The documentation for the Mishimoto Engineering is impressive and had me sold. The install was a breeze any my electric fans mounted to the radiator just like factory. I have seen a reduction in towing temp to about 200 degress. Prior to the install, i would stay around 220 to 230 degrees on even the slightest of grade.

My research had shown that with a few of the other 3 row aluminum radiators did not have the overflow connection design correctly. They did not have a flow reducing bushing which causes the engine to have a hard time warming up. The solutions to fix this was simple, put a washer in the overflow line at the radiator, but i happened on an open box Mishimoto radiator from Amazon that was about the same price as the no-name radiators, so it was a no brainer. The documentation for the Mishimoto Engineering is impressive and had me sold. The install was a breeze any my electric fans mounted to the radiator just like factory. I have seen a reduction in towing temp to about 200 degress. Prior to the install, i would stay around 220 to 230 degrees on even the slightest of grade.