SnowDrifter

Full Access Member

- Joined

- Sep 5, 2016

- Posts

- 2,405

- Reaction score

- 2,591

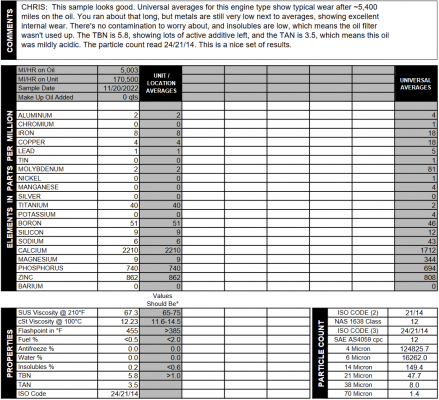

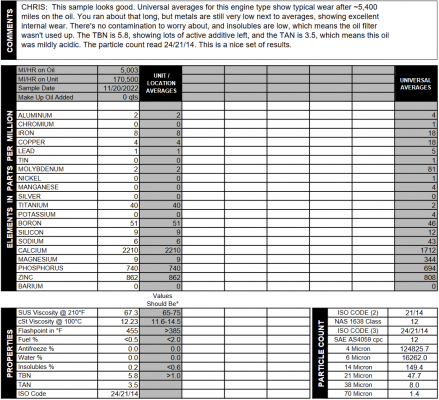

Figured I'd do a health check on my rig. Mainly just to poke at the casttech heads and see how those are. But also to see how my weird maintenance habits perform in the real world.

They came out pretty good, so, I figure I'll share my ways with y'all. Do with that what you will.

- Oil pump: Melling 295HV (oem pump had some cavitation wear, so in the f-it bucket it goes)

- Oil: Castrol 0w40 Euro Spec - preferred over 5w30 for various reasons. Numbers speak for themselves

- Filter: Fram XG3675 - synthetic media, 'long' filter. Included particle count. Someone smarter than me can discuss there

- Air filter: Standard mesh-backed dry filter. No oil wetted KN nonsense here.

General habits:

- PCV catch can is installed

- I drive my car soft until the oil comes up to temp. I took my hot oil pressure at 3k rpm and use that to self impose a 'redline' until it warms up to that point. In my configuration, that's 80 psi as per a digital readout. So, I cap my rpm/throttle to stay <=80psi as the thing warms up. Oil temperature lags quite a bit behind coolant temp!

- If the car has been sitting for more than a couple days, I'll crank the engine in 'flood clear' mode to get some oil before it starts up

- I don't idle to warm up. I drive gently. Once warm, I have no qualms about using the throttle

- I put a little TC-W3 rated 2 stroke oil in my fuel. 1oz/4gal. Roughly 500:1. Helps fuel economy a wee bit so, why not. Intuitively, might help with wear too.

- I generally don't turn the car off if I'm going to start it back up within a minute or 2 e.g. getting gas or grabbing mail

They came out pretty good, so, I figure I'll share my ways with y'all. Do with that what you will.

- Oil pump: Melling 295HV (oem pump had some cavitation wear, so in the f-it bucket it goes)

- Oil: Castrol 0w40 Euro Spec - preferred over 5w30 for various reasons. Numbers speak for themselves

- Filter: Fram XG3675 - synthetic media, 'long' filter. Included particle count. Someone smarter than me can discuss there

- Air filter: Standard mesh-backed dry filter. No oil wetted KN nonsense here.

General habits:

- PCV catch can is installed

- I drive my car soft until the oil comes up to temp. I took my hot oil pressure at 3k rpm and use that to self impose a 'redline' until it warms up to that point. In my configuration, that's 80 psi as per a digital readout. So, I cap my rpm/throttle to stay <=80psi as the thing warms up. Oil temperature lags quite a bit behind coolant temp!

- If the car has been sitting for more than a couple days, I'll crank the engine in 'flood clear' mode to get some oil before it starts up

- I don't idle to warm up. I drive gently. Once warm, I have no qualms about using the throttle

- I put a little TC-W3 rated 2 stroke oil in my fuel. 1oz/4gal. Roughly 500:1. Helps fuel economy a wee bit so, why not. Intuitively, might help with wear too.

- I generally don't turn the car off if I'm going to start it back up within a minute or 2 e.g. getting gas or grabbing mail

Last edited: