Levin37

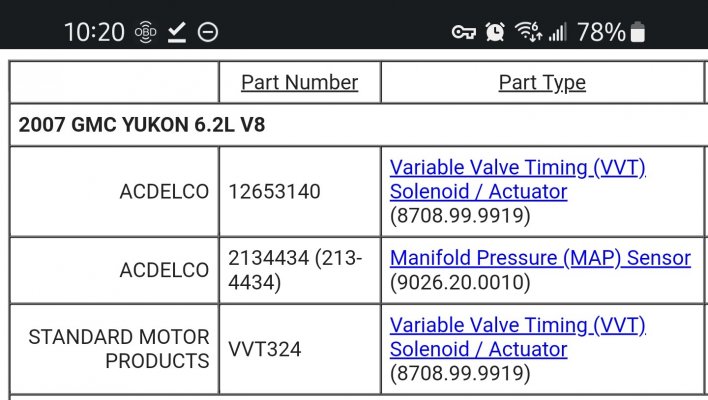

TYF Newbie

So it started about a year ago, once engine gets to operating temp (coolant needle straight up), the traction/stability light would come on, indicating an issue and then shortly after a p0011 code, “A” Camshaft Position Timing Over Advanced or System Performance Bank 1. Nothing would change in drivability it would just hinder my ability to use my remote start, if I forgot to clear the code, and of course loss of my stability and traction control. I would just reset the code end of day and all good, but I wanted to solve it for good so I wouldn't have to be doing that all winter. I bought a new Camshaft Position Sensor from Rock Auto and installed mid Oct. It was a pain, and took 2 days as it broke off coming out. Truck was ok the next day, not prefect but drivable so I drove it all day and had an oil change done at a quick lube place as it was close to being due. This is when all hell broke loose. Drove the truck home from there, something was off, stumbling idle, drop in oil pressure, misfiring, engine went into limp mode. Got it to my local garage and they suggested maybe the wrong oil was put in or they put in a high mileage additive or something (they deny both). So they suggested dump the oil, switch to standard oil to flush it out and then back to synthetic. Ran it for a week or so and the oil pressure was better but still dropped at idle, causing the vehicle to shake and almost stall. Started running 91/93 gas as to not cause any further detonation issues when pressure drops way down. Had it flushed again and back to synthetic. Oil pressure better yet again, but once the vehicle gets warmed up the pressure starts dropping at idle and then traction/stability lights like clockwork and then the P0011. Garage suggested an issue with the VVT system and quoted $1300 to pull it all apart but no guarantees. I decided to have them change the cam solenoid behind the water pump and see what happened. No real change. Truck still gets perfect oil pressure but once warmed up it drops. So with extensive reading of this forums I figured it had to be the oil pickup tube o-ring, ordered a new Melling pickup, o-rings and a high pressure/high volume pump. Garage quoted $1500 to change the pump and pickup, suggested only changing the pickup as the oil pump never goes bad in an LS, and pressure is great (until is isn't). So paid $700 for that as the oil pan gasket had to changed as well. Oil pressure better than ever, but after a day the same issues once warmed up, pressure doesn't drop as much but same codes and sometimes surging/vehicle shaking like its gonna stall. Further forum reading suggested the valley cover gasket, 8 o-rings that could all be leaking pressure. So I bought a new after market one, designed for AFM/DOD delete (of which I have neither), along with new intake manifold gaskets and valve cover gaskets as they were seeping a bit. Pulled it all apart last weekend, all went back together well, cleaned everything up real nice, valves, springs, lifters all look good, appears to be minor scoring on the cam journals from what I could see below the valley cover. Oil pressure sensor was new last year and I don't have the screen below it. Truck drove great Mon, didn't drive far but oil pressure best its ever been. But Tues all back to normal, once the coolant needle points up, traction/stability lights and then the P0011. Random surging/rumbling at idle and oil pressure gets real low, not as low as before but low, truck is drivable but annoying. Now my question for everyone is how to proceed. I have read that once you get the P0011 code and it cant be solved then the engine is end of life, source a new one and swap it out. I'm looking into a few now, rebuilt and crate. But can this be solved without a full swap? is it a worn cam issue? Should I buy an aftermarket cam, either VVT with the limiter or swap to non-VVT to eliminate the whole subsystem causing the issue. Is the issue with the VVT caused by a further low oil pressure issue or is the VVT system causing the low oil pressure. I was positive once I solved the low pressure the P0011 would never come back but I have exhausted my resources. I have a tech2 so I can get exact readings but haven't used it much yet so not sure how to send VVT requests etc. Any and all input welcome. Thanks in advance.