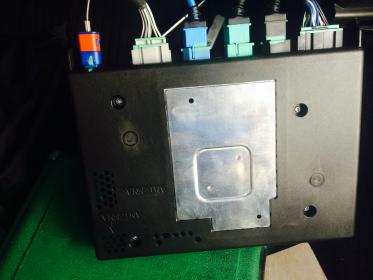

Hi all, I reinstalled the HMI yesterday and discovered that I damaged the jumped connectors with too thick of gauge wire. I had to repair the connector and will end up replacing it. It is CRITICAL that you do not overstress the connectors on female harness that you jump. I soldered a stranded 18 gauge and it was too big and I knew it after I inserted it. That is why I said before, please start with a very small 22 gauge sold wire and be very gentle. I'd love to hear others experience. If you aren't comfortable doing such then you should be prepared to leave the vehicle inoperable until you reinstall the HMI module.

I highly recommend testing the connection once you reinstall the HMI module before reassembling the glove box. With the vehicle running you should wiggle the J1 connector and make sure it has solid contact. Connection failure during operation could result in loss of key vehicle systems including power steering.