Dan Acosta

Full Access Member

- Joined

- Feb 26, 2017

- Posts

- 186

- Reaction score

- 41

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

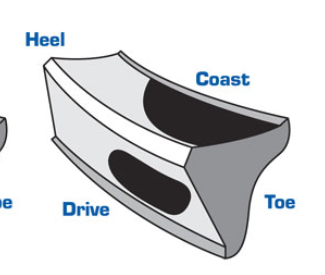

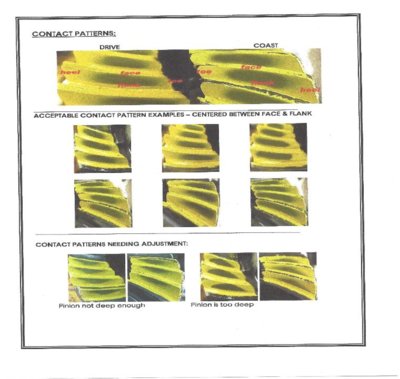

By too deep, do you mean to deep in the housing or too deep into the gear? Backlash is at .007its been a while since I've touched one but to me it looks like the pattern is too deep, I'm no gear expert either but I don't really like how the drive side looks, its to far down the toe, and the coast is just hugging the root. Whats your backlash set to? whats the pinion depth atm? I would make sure you are within spec backlash first and then adjust the depth after a pattern check, remove a few 2-4 thou at a time that way you can see the gradual shift. Here is what mine ended up looking like at .034 pinion depth can't recall the backlash but it was tight as called by the gear manufacturer. somewhere between 3-6 thou some might ask for 6-10 really depends on the manufacturer.

View attachment 211685 View attachment 211686 View attachment 211687

Current Pinion shim is .033 while the one on the oem gears is .020. The patterns are fairly rounded, and I think the appearance of closeness to the root is a lighting issue. I have been up and down with the pinion shims, and the patterns are fairly even (coast & drive). Once I go either way, the patterns move in opposite directions (towards the toe & heel). I may try taking a few out again before I take it to a pro. I will post pics if I do. It just seems the more I take out, I start to turn the ring by the ***/top of the pinion.