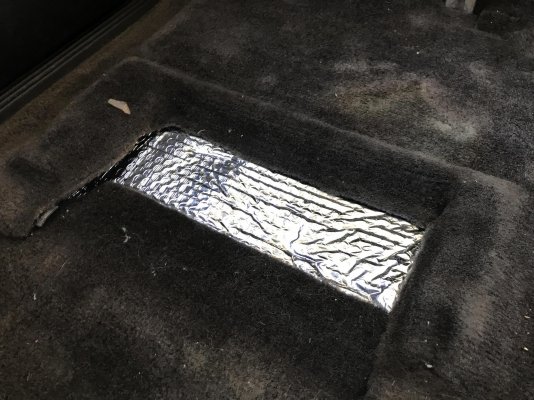

Thought I'd start a thread detailing my Suburban camper build. My girlfriend and I have been working remotely since March (and will for the foreseeable future) so our commute is nonexistent. We decided to sell our relatively boring cars and consolidate down to one vehicle more suitable for long road trips and camping. We looked at a few other SUVs and vans/minivans but the Suburban or Yukon XL was really the only candidate. There are compromises to every camper platform, but we wanted something that was both decent to drive around town and reasonably competent off road and in snow.

So we picked up a 1 owner 2011 Z71 Suburban 4x4 with 147k around a month ago. The G80 diff was a must for me, and a 2 speed transfer case was highly preferable. In hindsight we probably would've been better served with Autoride since the vast majority of our miles are on pavement, but the Z71 is comfortable enough and we got a great deal on this.

More to come...

So we picked up a 1 owner 2011 Z71 Suburban 4x4 with 147k around a month ago. The G80 diff was a must for me, and a 2 speed transfer case was highly preferable. In hindsight we probably would've been better served with Autoride since the vast majority of our miles are on pavement, but the Z71 is comfortable enough and we got a great deal on this.

More to come...