Hey all! Located in central florida, just north of Orlando. I just bought a 2007 Yukon XL Denali. 161k miles, AWD/6.2/6spd. This is for my 'rebuild'/repair thread haha. It needs a lot of TLC, but the body is mint(I'm from the north, to ME its mint anyways. Zero rust, has typical paint fade but otherwise its G2G), and it runs/drives pretty well.

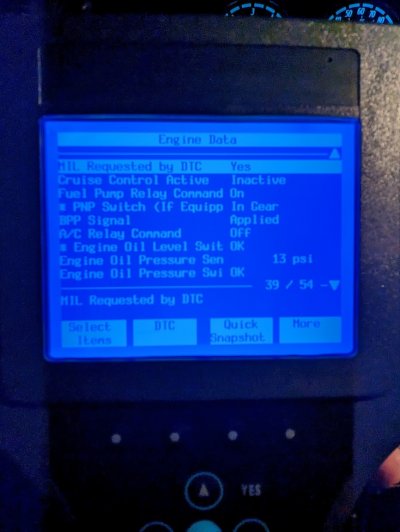

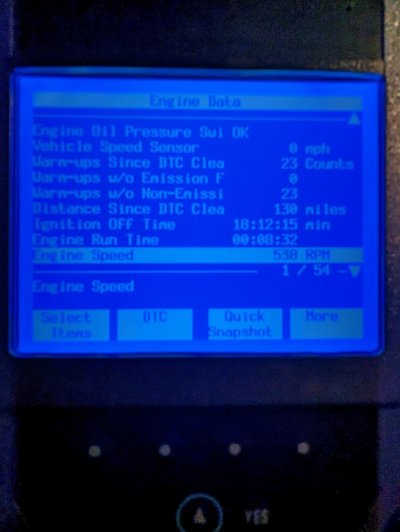

The only 'major' concern initially for me is that after driving for a while (I'd say about 20-30 mins), it will stumble and die coming to a stop at a traffic light (dies at the light or just before at like 2 mph). It is then hard as hell to get started. it has done it 3 times(oil was near the lowest dot on dipstick, I've added about a 1/2 quart of lucas), the last time I got it started fast by holding pedal to floor then playing with throttle to keep it running. When its been running for 15 or so mins oil pressure gets down to the 10-psi range especially when idling at a light though press light doesn't illuminate.

This is not my primary vehicle, and is planned to be a 'family/friends' family trip type of vehicle. So I'll be taking my time with these repairs lol.

I did do an intro post a bit back. Only had a couple codes via my basic scan tool. So I got a tech 2 scanner to find all the codes.

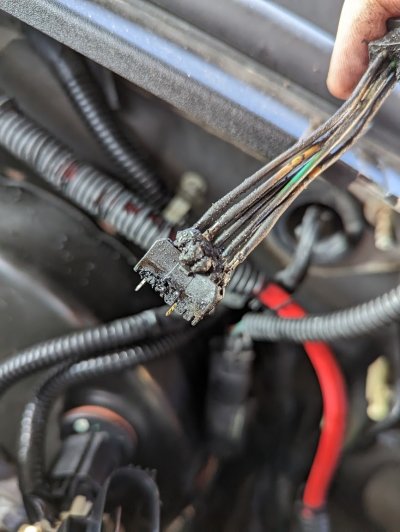

Heated seats (front seats) dont work (light turns on then off after apprx 30 secs), power seats dont work (drivers side clicks doesnt move, pass side doesnt do anything). Pedal adjust button clicks but doesnt move. Pass side window front/rear dont work (both just click). I found a disconnected wire I cant find the connection for by the battery (large 2 prong plug), and a melted wire that was tucked underneath the battery, and I will try and post a picture of).

I cant connect a new key fob, gets to the point where you click the check mark to 'learn' and nothing happens, it just stays there. Check mark button works otherwise no prob. Had a locksmith attempt with his tool as well, no luck. It does have a viper alarm system installed (I would much prefer the factory, theft isnt really an issue). .

I have lights for check engine, abs, traction control, stabilitrack, service suspension, and service rear park aid.

It has 34 DTCs in total. I have experience as a mechanic, but not as a professional. What does symptom mean to the right of the code #? Anything else I should grab? I was told to grab history as well, I need to do that.

P0455 (Symptom 00), P0430 (Symptom 00), P0420 (Symptom 00), P0011(Sym 00)

C0561(Sym 71), C0045 (Sym 00)

U0184(Sym 00)(B1095, B1085, B1055, B1045, B1035, B1025 are for Amplifier as it has an aftermarket head-unit I'm assuming)

U0214 (Sym 00), B0961 (Sym 06),

B2430 (Sym 0C), B2180 (Sym 0C), B2425(Sym 0C), B1935 (Sym 0C), B1850(Sym 01), B2365(Sym 06), B3920(Sym 02). All seat related codes

B1370 (Sym 06), B1600 (Sym 02), , B1011(Sym 71), B1544

C0580(Sym 04, Sym 01), C0575(Sym 04, 01), U0208(Sym 00), B3060 (Sym 00), B1544 (Sym 04)

Sorry for the lengthy post!! I can post the details of each code if thats better. Any help is much appreciated as I tackle this, and handle it piece by piece.

The only 'major' concern initially for me is that after driving for a while (I'd say about 20-30 mins), it will stumble and die coming to a stop at a traffic light (dies at the light or just before at like 2 mph). It is then hard as hell to get started. it has done it 3 times(oil was near the lowest dot on dipstick, I've added about a 1/2 quart of lucas), the last time I got it started fast by holding pedal to floor then playing with throttle to keep it running. When its been running for 15 or so mins oil pressure gets down to the 10-psi range especially when idling at a light though press light doesn't illuminate.

This is not my primary vehicle, and is planned to be a 'family/friends' family trip type of vehicle. So I'll be taking my time with these repairs lol.

I did do an intro post a bit back. Only had a couple codes via my basic scan tool. So I got a tech 2 scanner to find all the codes.

Heated seats (front seats) dont work (light turns on then off after apprx 30 secs), power seats dont work (drivers side clicks doesnt move, pass side doesnt do anything). Pedal adjust button clicks but doesnt move. Pass side window front/rear dont work (both just click). I found a disconnected wire I cant find the connection for by the battery (large 2 prong plug), and a melted wire that was tucked underneath the battery, and I will try and post a picture of).

I cant connect a new key fob, gets to the point where you click the check mark to 'learn' and nothing happens, it just stays there. Check mark button works otherwise no prob. Had a locksmith attempt with his tool as well, no luck. It does have a viper alarm system installed (I would much prefer the factory, theft isnt really an issue). .

I have lights for check engine, abs, traction control, stabilitrack, service suspension, and service rear park aid.

It has 34 DTCs in total. I have experience as a mechanic, but not as a professional. What does symptom mean to the right of the code #? Anything else I should grab? I was told to grab history as well, I need to do that.

P0455 (Symptom 00), P0430 (Symptom 00), P0420 (Symptom 00), P0011(Sym 00)

C0561(Sym 71), C0045 (Sym 00)

U0184(Sym 00)(B1095, B1085, B1055, B1045, B1035, B1025 are for Amplifier as it has an aftermarket head-unit I'm assuming)

U0214 (Sym 00), B0961 (Sym 06),

B2430 (Sym 0C), B2180 (Sym 0C), B2425(Sym 0C), B1935 (Sym 0C), B1850(Sym 01), B2365(Sym 06), B3920(Sym 02). All seat related codes

B1370 (Sym 06), B1600 (Sym 02), , B1011(Sym 71), B1544

C0580(Sym 04, Sym 01), C0575(Sym 04, 01), U0208(Sym 00), B3060 (Sym 00), B1544 (Sym 04)

Sorry for the lengthy post!! I can post the details of each code if thats better. Any help is much appreciated as I tackle this, and handle it piece by piece.

Last edited: