jeffm333

TYF Newbie

Posting in "general discussion", wasn't sure if ECM/BCM complex electrical system issues should be in "Audio and Electronics" or somewhere else?

I have found myself in quite the pickle... I've already done quite a bit of troubleshooting and I will try to outline everything pertinent plus the conditions that led me here. 2013 Suburban Z71.

CURRENT WIRING CONDITIONS AND SYMPTOMS:

I have the alternator wire and starter wire disconnected from the starter battery. (the starter wire is not fused, and the alternator cable had a wear spot potentially causing a short to metal engine components - but more on that later) I am only connecting the main positive accessory line to the battery to troubleshoot and keep things simple for now. I do not expect having these disconnected to be the cause of my symptoms, but if anyone feels differently please let me know.

Upon making the connection (between battery positive terminal and the positive lead to vehicles systems via the main under-hood fuse box), numerous accessories immediately power on and remain powered on - the horn, the windshield washer pump (annoyingly but humorously spraying me with windshield washer fluid), A/C blower, high and low beams, DRL, and numerous other systems). Just to limit some of this behavior I pulled the fuses of the washer fluid pump and the headlights and the horn (it was deafening in the garage). The dash display does not power on whatsoever, key in any ignition position does nothing. This feels like some kind of massive short or wire-harness criss-cross; I've detailed below all the things I've done to find such a cause and have failed to find anything wrong. FIRST MAIN QUESTION IN THIS POST: If a BCM/ECM either gets fried or freaked out via being shorted or some other type foolish thing I did to it during the install, would the truck ever exhibit this kind of behavior? (It seems like a ridiculous set of symptoms, but I've never had a bad ECM/BCM with any of my GM's so have no experience in what happens when they fail)

THE MORE COMPLETE STORY:

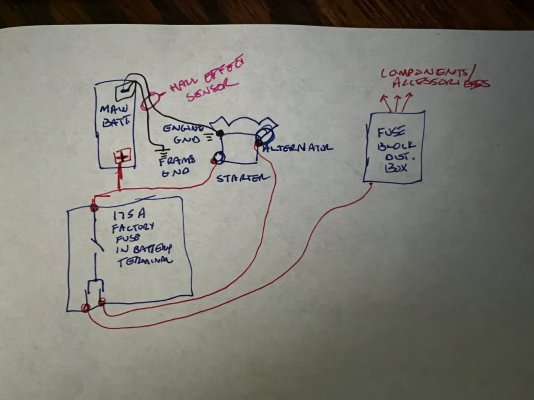

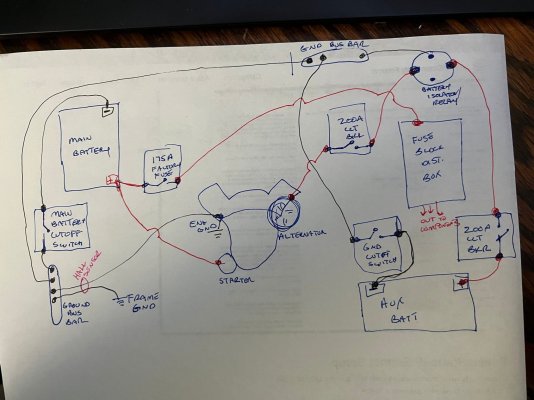

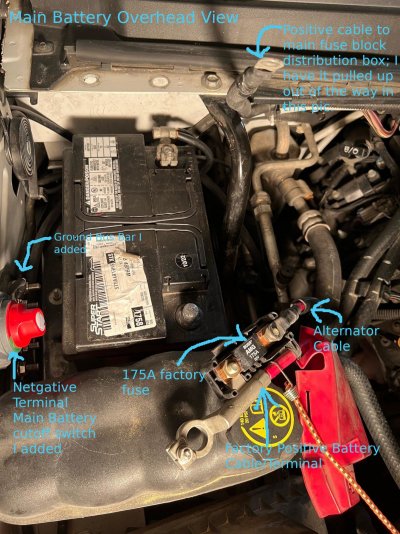

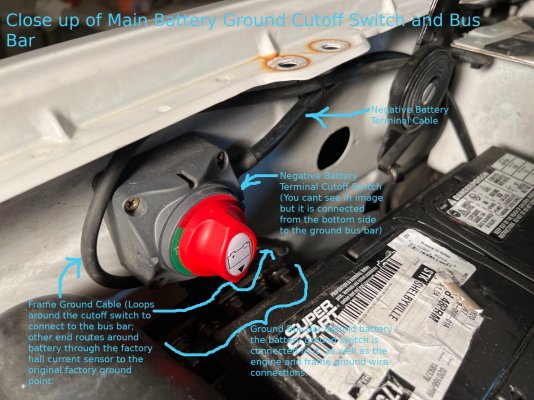

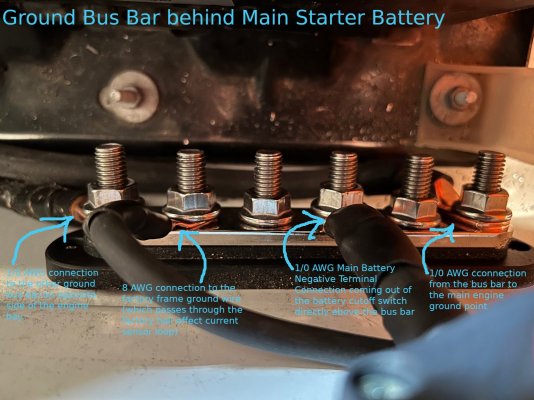

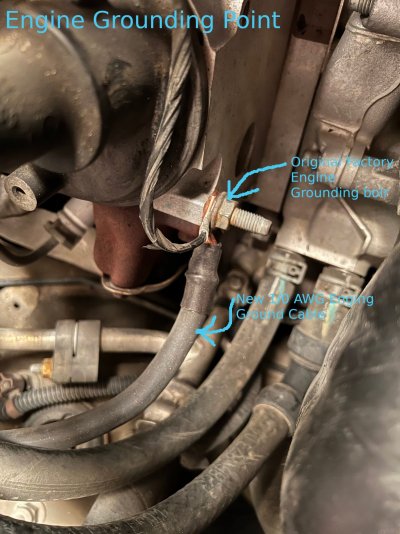

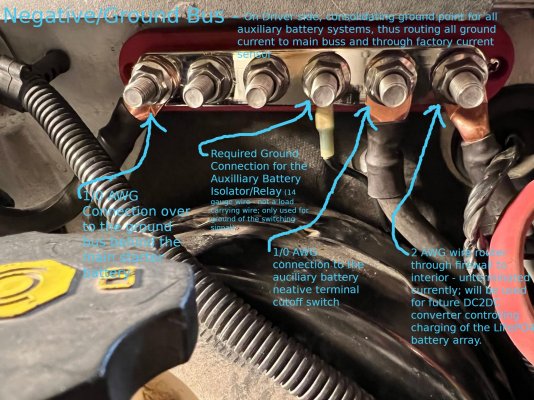

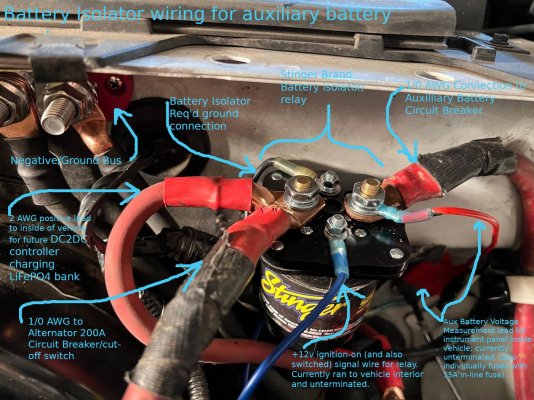

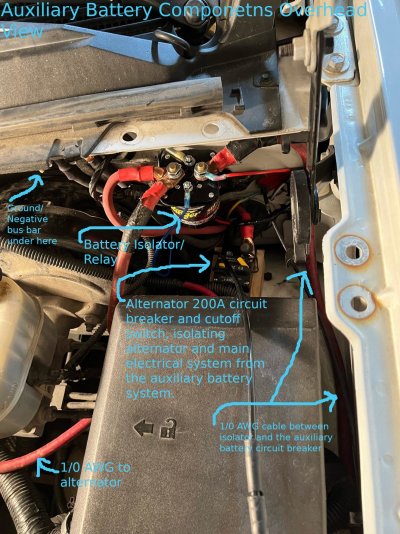

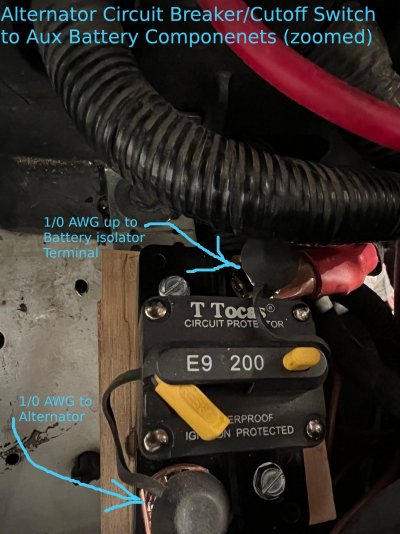

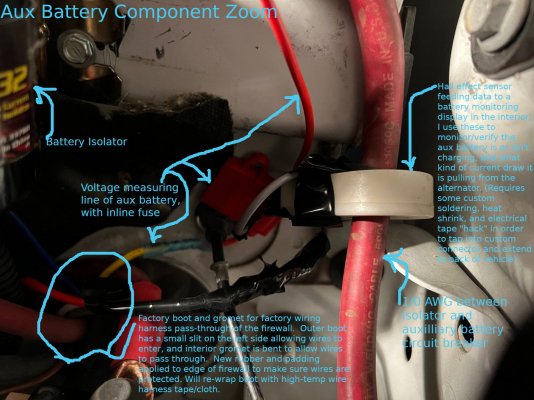

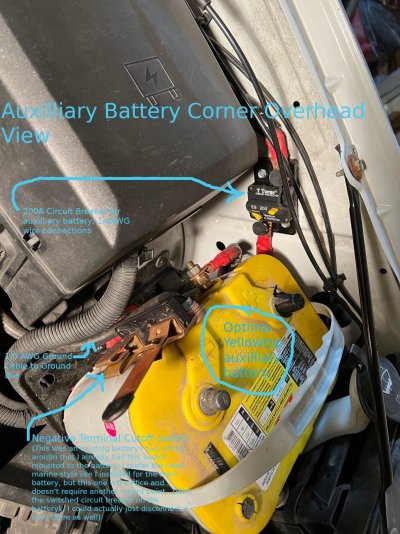

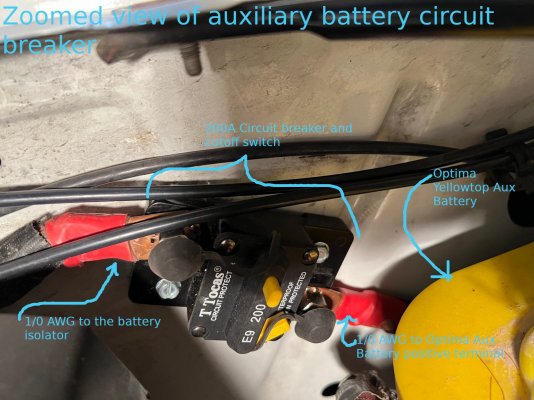

First off: This is very likely triggered by something I have done while installing a secondary battery under the hood. I've done this same work on my Tahoe and multiple other vehicles over the years; it's pretty straightforward for a tinkering electrical engineer with respectable automotive maintenance experience; I've never had any major issues like this. I generally follow all best-practices methods; batteries disconnected for entire install process; I add negative-terminal cutoff switches to both starter battery and auxiliary battery, I make sure both batteries have fuses and/or in-line circuit breakers, I use a battery isolator/relay to isolate the auxiliary battery, I over-engineer with very heavy gauge wire and all-copper quality ring-terminals professionally crimped, etc. For this install, I can't find a single obvious thing wrong. Not only that, I had all of my secondary battery install completely isolated - all fuses/breakers off, secondary battery ground disconnected. When I connected the starter battery after completing all the work, I left the secondary system completely disconnected; wanted to make sure truck operated normally as expected first. Thus, it is unlikely the actual secondary battery wiring/connections are a direct factor. That being said, I have drilled and mounted bus bars, battery switches/circuit breakers, battery isolator relay, etc. It is feasible to have drilled into an interior fender wall under the hood, and drove a screw right into a wiring harness. I have double-checked all of these screw/mount points, even removed a handful of them, and can find absolutely no evidence of this. They are all in areas I believe to be very safe to drill into, and have had no issues doing so in the past on Gm trucks. Further down I will explain more details of what has been done and what I've looked for and attempted.

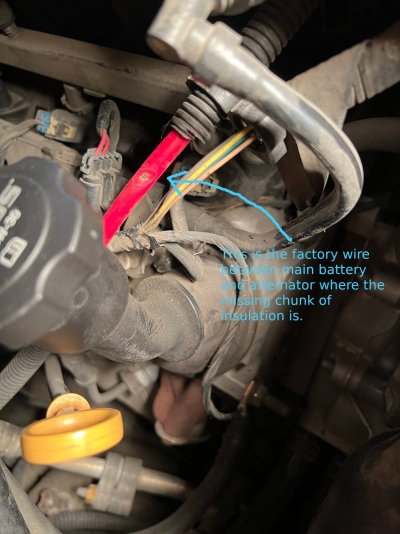

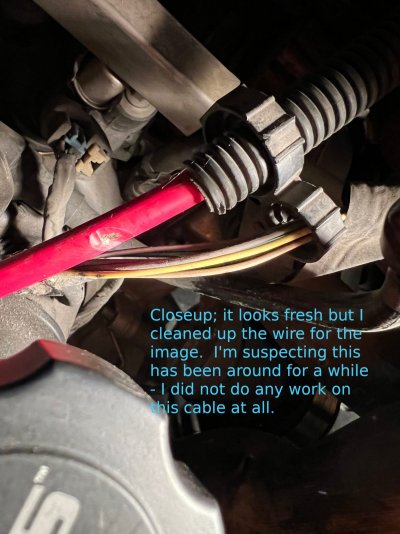

When I first connected the starter battery's positive battery terminal, sparks flew more than I expected, but were short lived. Seemed like way more than your typical little arc/spark upon reconnect. Sure enough, I checked the 175A in-line fuse in the harness, and it was blown. (To give people background who aren't familiar with this year GM truck - the positive battery terminal is a fancy little fellow that has multiple connections to it; one is a direct and unfused link to the starter. Then, another branch feeds the 175A fuse, which then has two wires connected to it utilizing the fuse - one for all the accessories and electrical system of the truck, and one is a direct wire to the alternator.) Upon detailed examination of the alternator wire, I did find a bare spot that had worn off - so this could be the culprit causing the short if that bare area touched a valve cover or aluminum head or a fuel rail or whatever. It looked old so it's probably been there a while, and me moving the cable around while working probably helped it find it's way to some bare metal somewhere on the top of the engine. This seems like a likely culprit, but I can't be 100% positive this happened or caused my issues. Thoughts? (I will just replace this alternator wire with a nice beefy 1/0 AWG new cable later; for now I don't need the alternator so it is just disconnected)

So after this, since I didn't have another fuse and it was late and I wanted to test to see if there was a short somewhere else in case this alternator wire wasn't the only short. I connected a 100A breaker to the positive cable to the trucks accessories (to the main fuse box), then connected it to the positive terminal of the battery... expecting (hoping) the circuit breaker wouldn't trip, nothing scary would happen, and I could put the car in ignition-on state and verify things were working and there was not some other short. Well the circuit did not blow, but this is when all hell broke loose - the horn blares continuously and the washer fluid incident occurred, tons of accessories just power on even though the key is not in the ignition, and is where I am now. (Worthy of note the entire dash cluster is dead and the key changes nothign in any ignition/on/accessory state)

This feels like some kind of massive short or re-wiring issue, where all these components are immediately getting power when they shouldn't. As I stated above, I changed nothing of the trucks electrical system relating to the factory accessories. I'm reasonably experienced at this dual-battery install in GM trucks and have double-checked everywhere I put a screw into any piece of metal and checked behind it as best I could. I haven't messed with the under-hood fuse box or screwed anything into it whatsoever. I can find nothing out of place.

Unlikely to be related - but while the batteries were all disconnected for the wiring work I also had removed all the middle and rear seats along with some rear interior panels; I double checked all the wiring harnesses from the rear seats and around all panels I removed and verified there was nothing shorted or touching the metal frame, etc.

I ran additional accessory wires into the main cabin through the main wiring harness grommet on the drivers side firewall. There is lots of space here; removing the boots/grommets and/or cutting a small hole through them to feed wires is fairly easy and a cleaner/safer solution than drilling new holes into the firewall (IMO), thus I prefer this method. Of course there is always risk when monkeying around near any wiring, so I've quadruple checked this work and can find no cut/frayed wires, and the new wires that are fed through are clean and not touching or cutting into any frame metal. (The wires I added ran through for future modifications and are un-terminated within the vehicle, and either unterminated under the hood or connected with the secondary battery components which are all disconnected and isolated).

I continuity tested every fuse in the interior drivers side fuse block, and in the engine compartment fuse box. Only one blown fuse, labeled "amp", I presume is the radio system amplifier. I can't even be positive if this fuse blew from this issue, or if this was already blown when I got the truck. (Just purchased this truck - had it less than a week; radio worked when I drove it but I didn't really test all the read DVD systems or all the speakers or even crank it up; the radio wasn't a priority for the purchase) Mentioning it just in case it could give clues or be related.

MY MAIN THEORIES:

1) I drilled into a wiring harness or otherwise frayed some system wires. I've checked this over and over and can find no evidence of this. Plus, the level of systems that are not working now, I would have had to drill through a TON of wires to get anything like this behavior. I am seriously discounting this as a possibility. Thoughts?

2) When running the wires through the firewall under the dash, I unplugged all the main wiring harness connections and un-clipped the mount from it's seat to move it out of my way. Could I have criss-crossed one of the connection plugs when I rewired it? This could certainly account for some crazy behavior like this for a multitude of symptoms. This was actually my most suspected culprit - but upon multiple checks and reviews plus comparing color-coding of the connectors to pictures of expected positions online, everything looks completely fine. (Plus, it would be HARD to plug these in wrong - the wiring harness groupings are all near-perfect length to where you'd have to really try to plug one into the wrong socket - and most simply wouldn't reach or fit) In any case, I'm not done verifying here; if anyone has a 2007-2013 suburban/tahoe/silverado and wants to snap a pic or compare to my pics, let me know. If anyone has any ideas of something else I could have done under the dash to cause this, let me know. If anyone has a model year of this truck and is a tech or highly familiar with the electrical systems on these trucks, please chime in or DM me.

3) When the alternator wire shorted against the engine (presumably), did shorting the cars system out a few seconds before the 175A fuse blew cause havoc with the BCM/ECM modules? Could such a thing mess 'em up or fry them outright? Could the alternator cable have shorted to some other sensor wire or caused current to flow into ECM/BCM via some unintended path thus torching one or both of them? This seems possible but unlikely - but honestly I've been lucky to not have any major headaches like this or have an ECM/BCM fail on my so I just don't know what could cause it and what the symptoms would be. Any input here would be great.

Any other ideas or input is welcome. Anyone who wants to make fun of me being sprayed with washer fluid and being deafened by the horn at midnight in the middle of the weak all due to some bonehead things I've likely done and am missing... feel free to indulge; I am likely deserving. Atleast I didn't get electrocuted at the same time.

I have found myself in quite the pickle... I've already done quite a bit of troubleshooting and I will try to outline everything pertinent plus the conditions that led me here. 2013 Suburban Z71.

CURRENT WIRING CONDITIONS AND SYMPTOMS:

I have the alternator wire and starter wire disconnected from the starter battery. (the starter wire is not fused, and the alternator cable had a wear spot potentially causing a short to metal engine components - but more on that later) I am only connecting the main positive accessory line to the battery to troubleshoot and keep things simple for now. I do not expect having these disconnected to be the cause of my symptoms, but if anyone feels differently please let me know.

Upon making the connection (between battery positive terminal and the positive lead to vehicles systems via the main under-hood fuse box), numerous accessories immediately power on and remain powered on - the horn, the windshield washer pump (annoyingly but humorously spraying me with windshield washer fluid), A/C blower, high and low beams, DRL, and numerous other systems). Just to limit some of this behavior I pulled the fuses of the washer fluid pump and the headlights and the horn (it was deafening in the garage). The dash display does not power on whatsoever, key in any ignition position does nothing. This feels like some kind of massive short or wire-harness criss-cross; I've detailed below all the things I've done to find such a cause and have failed to find anything wrong. FIRST MAIN QUESTION IN THIS POST: If a BCM/ECM either gets fried or freaked out via being shorted or some other type foolish thing I did to it during the install, would the truck ever exhibit this kind of behavior? (It seems like a ridiculous set of symptoms, but I've never had a bad ECM/BCM with any of my GM's so have no experience in what happens when they fail)

THE MORE COMPLETE STORY:

First off: This is very likely triggered by something I have done while installing a secondary battery under the hood. I've done this same work on my Tahoe and multiple other vehicles over the years; it's pretty straightforward for a tinkering electrical engineer with respectable automotive maintenance experience; I've never had any major issues like this. I generally follow all best-practices methods; batteries disconnected for entire install process; I add negative-terminal cutoff switches to both starter battery and auxiliary battery, I make sure both batteries have fuses and/or in-line circuit breakers, I use a battery isolator/relay to isolate the auxiliary battery, I over-engineer with very heavy gauge wire and all-copper quality ring-terminals professionally crimped, etc. For this install, I can't find a single obvious thing wrong. Not only that, I had all of my secondary battery install completely isolated - all fuses/breakers off, secondary battery ground disconnected. When I connected the starter battery after completing all the work, I left the secondary system completely disconnected; wanted to make sure truck operated normally as expected first. Thus, it is unlikely the actual secondary battery wiring/connections are a direct factor. That being said, I have drilled and mounted bus bars, battery switches/circuit breakers, battery isolator relay, etc. It is feasible to have drilled into an interior fender wall under the hood, and drove a screw right into a wiring harness. I have double-checked all of these screw/mount points, even removed a handful of them, and can find absolutely no evidence of this. They are all in areas I believe to be very safe to drill into, and have had no issues doing so in the past on Gm trucks. Further down I will explain more details of what has been done and what I've looked for and attempted.

When I first connected the starter battery's positive battery terminal, sparks flew more than I expected, but were short lived. Seemed like way more than your typical little arc/spark upon reconnect. Sure enough, I checked the 175A in-line fuse in the harness, and it was blown. (To give people background who aren't familiar with this year GM truck - the positive battery terminal is a fancy little fellow that has multiple connections to it; one is a direct and unfused link to the starter. Then, another branch feeds the 175A fuse, which then has two wires connected to it utilizing the fuse - one for all the accessories and electrical system of the truck, and one is a direct wire to the alternator.) Upon detailed examination of the alternator wire, I did find a bare spot that had worn off - so this could be the culprit causing the short if that bare area touched a valve cover or aluminum head or a fuel rail or whatever. It looked old so it's probably been there a while, and me moving the cable around while working probably helped it find it's way to some bare metal somewhere on the top of the engine. This seems like a likely culprit, but I can't be 100% positive this happened or caused my issues. Thoughts? (I will just replace this alternator wire with a nice beefy 1/0 AWG new cable later; for now I don't need the alternator so it is just disconnected)

So after this, since I didn't have another fuse and it was late and I wanted to test to see if there was a short somewhere else in case this alternator wire wasn't the only short. I connected a 100A breaker to the positive cable to the trucks accessories (to the main fuse box), then connected it to the positive terminal of the battery... expecting (hoping) the circuit breaker wouldn't trip, nothing scary would happen, and I could put the car in ignition-on state and verify things were working and there was not some other short. Well the circuit did not blow, but this is when all hell broke loose - the horn blares continuously and the washer fluid incident occurred, tons of accessories just power on even though the key is not in the ignition, and is where I am now. (Worthy of note the entire dash cluster is dead and the key changes nothign in any ignition/on/accessory state)

This feels like some kind of massive short or re-wiring issue, where all these components are immediately getting power when they shouldn't. As I stated above, I changed nothing of the trucks electrical system relating to the factory accessories. I'm reasonably experienced at this dual-battery install in GM trucks and have double-checked everywhere I put a screw into any piece of metal and checked behind it as best I could. I haven't messed with the under-hood fuse box or screwed anything into it whatsoever. I can find nothing out of place.

Unlikely to be related - but while the batteries were all disconnected for the wiring work I also had removed all the middle and rear seats along with some rear interior panels; I double checked all the wiring harnesses from the rear seats and around all panels I removed and verified there was nothing shorted or touching the metal frame, etc.

I ran additional accessory wires into the main cabin through the main wiring harness grommet on the drivers side firewall. There is lots of space here; removing the boots/grommets and/or cutting a small hole through them to feed wires is fairly easy and a cleaner/safer solution than drilling new holes into the firewall (IMO), thus I prefer this method. Of course there is always risk when monkeying around near any wiring, so I've quadruple checked this work and can find no cut/frayed wires, and the new wires that are fed through are clean and not touching or cutting into any frame metal. (The wires I added ran through for future modifications and are un-terminated within the vehicle, and either unterminated under the hood or connected with the secondary battery components which are all disconnected and isolated).

I continuity tested every fuse in the interior drivers side fuse block, and in the engine compartment fuse box. Only one blown fuse, labeled "amp", I presume is the radio system amplifier. I can't even be positive if this fuse blew from this issue, or if this was already blown when I got the truck. (Just purchased this truck - had it less than a week; radio worked when I drove it but I didn't really test all the read DVD systems or all the speakers or even crank it up; the radio wasn't a priority for the purchase) Mentioning it just in case it could give clues or be related.

MY MAIN THEORIES:

1) I drilled into a wiring harness or otherwise frayed some system wires. I've checked this over and over and can find no evidence of this. Plus, the level of systems that are not working now, I would have had to drill through a TON of wires to get anything like this behavior. I am seriously discounting this as a possibility. Thoughts?

2) When running the wires through the firewall under the dash, I unplugged all the main wiring harness connections and un-clipped the mount from it's seat to move it out of my way. Could I have criss-crossed one of the connection plugs when I rewired it? This could certainly account for some crazy behavior like this for a multitude of symptoms. This was actually my most suspected culprit - but upon multiple checks and reviews plus comparing color-coding of the connectors to pictures of expected positions online, everything looks completely fine. (Plus, it would be HARD to plug these in wrong - the wiring harness groupings are all near-perfect length to where you'd have to really try to plug one into the wrong socket - and most simply wouldn't reach or fit) In any case, I'm not done verifying here; if anyone has a 2007-2013 suburban/tahoe/silverado and wants to snap a pic or compare to my pics, let me know. If anyone has any ideas of something else I could have done under the dash to cause this, let me know. If anyone has a model year of this truck and is a tech or highly familiar with the electrical systems on these trucks, please chime in or DM me.

3) When the alternator wire shorted against the engine (presumably), did shorting the cars system out a few seconds before the 175A fuse blew cause havoc with the BCM/ECM modules? Could such a thing mess 'em up or fry them outright? Could the alternator cable have shorted to some other sensor wire or caused current to flow into ECM/BCM via some unintended path thus torching one or both of them? This seems possible but unlikely - but honestly I've been lucky to not have any major headaches like this or have an ECM/BCM fail on my so I just don't know what could cause it and what the symptoms would be. Any input here would be great.

Any other ideas or input is welcome. Anyone who wants to make fun of me being sprayed with washer fluid and being deafened by the horn at midnight in the middle of the weak all due to some bonehead things I've likely done and am missing... feel free to indulge; I am likely deserving. Atleast I didn't get electrocuted at the same time.