First thing i needed to do was remove the master cylinder (after bending new lines) and bench bleed it for final install. This is the contraption I made to cycle the fluid back into the reservoir. It took about 20 full pumps to remove all air bubbles.

Not sure what happened to the oil dipstick bracket but all i had left was a tube with no way to stabilize it. I took a washer, and a small piece of (probably) 3/16th stainless rod, bent it, and welded them together to make a makeshift bracket that attaches to a coil pack bracket bolt.

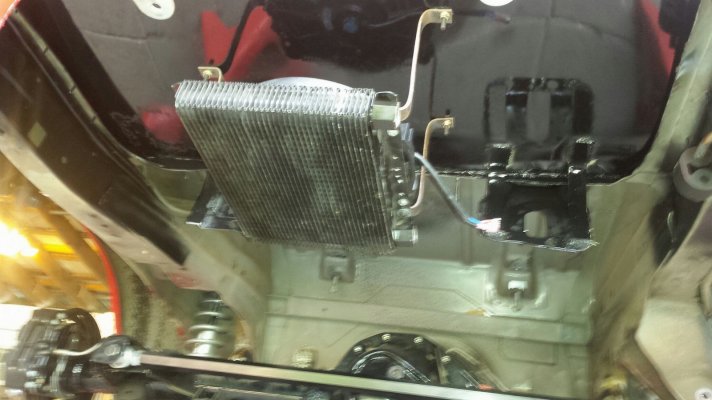

Dropped the motor on the k member

I originally took the wipers out and cut some of the cowl back (under the windshield). I did the best I could with the engine in the car. It was time consuming and I had to make a bunch of small cuts. Now that the engine is out I wasnt gonna waste the opportunity to complete the cut. My focus was the metal over the engine, and since i kept the plastic cowl cover, i have to leave some metal at the ends to support it. Here is what it looks like after we got through. This will make working on the top and rear of the engine so much easier.

Cut the floorboard for the trans plug and put some red paint on the cuts. Red brake lines never hurt nobody. This is required or you wont be able to plug the trans in.

Here is most of the stuff I removed from the car. The red is the cowl, the black brackets are for fog lights, horns on the left, then you have metal fuel line and metal exhaust shields. I threw this whole pile behind my wife's bushes in the back yard.

A few cuss words and a couple hours later.....

Not sure what happened to the oil dipstick bracket but all i had left was a tube with no way to stabilize it. I took a washer, and a small piece of (probably) 3/16th stainless rod, bent it, and welded them together to make a makeshift bracket that attaches to a coil pack bracket bolt.

Dropped the motor on the k member

I originally took the wipers out and cut some of the cowl back (under the windshield). I did the best I could with the engine in the car. It was time consuming and I had to make a bunch of small cuts. Now that the engine is out I wasnt gonna waste the opportunity to complete the cut. My focus was the metal over the engine, and since i kept the plastic cowl cover, i have to leave some metal at the ends to support it. Here is what it looks like after we got through. This will make working on the top and rear of the engine so much easier.

Cut the floorboard for the trans plug and put some red paint on the cuts. Red brake lines never hurt nobody. This is required or you wont be able to plug the trans in.

Here is most of the stuff I removed from the car. The red is the cowl, the black brackets are for fog lights, horns on the left, then you have metal fuel line and metal exhaust shields. I threw this whole pile behind my wife's bushes in the back yard.

A few cuss words and a couple hours later.....