Quick update, I was on the hunt for an intake and my buddy (thanks Randy C) had an LS2 laying around for cheap so I went and grabbed it. I decided to give it a "fast" type look and only paint the upper shell. Just went with the same graphite color i been using.

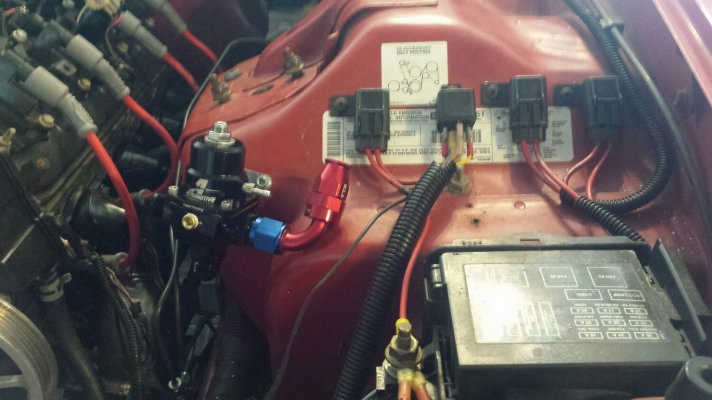

Had to use an alternative set of fuel rail brackets and trim my spacers down by about 1/3 but everything seems to fit nice. Also, I ordered the FAST fat orings for the bottom of the injectors since everything LS2 and later have bigger injector holes then LS1 stuff. 146020COR is the part number. 3 bar MAP sensor is in place, and the stock wiring is gonna have to be extended.

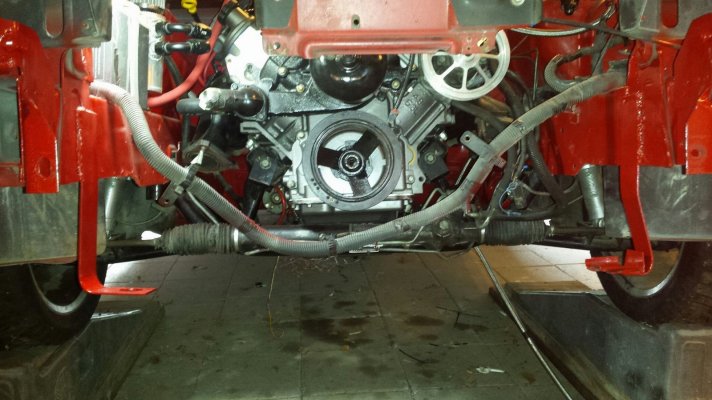

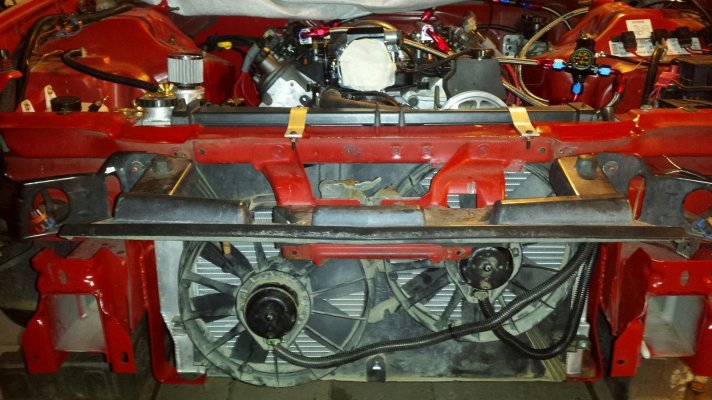

The black fittings are -10 for the catchcan to valve covers, along with matching -10 black nylon lined hose, and the rest of the fittings are the elbows to come off the rails, then random vacuum line, an exhaust reducer (more on that later) and the Honda alternator. Yep my daily is down so I will be fixing it instead of doing race car stuff.

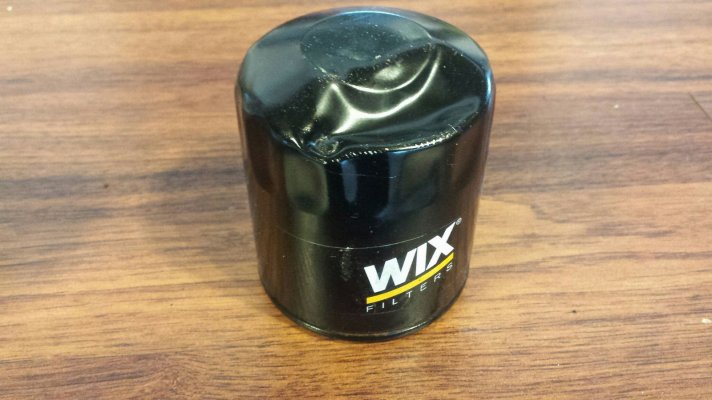

Super fast delivery....this is the PCV delete model, no vent tube. 92mm.

But that intake has no provisions for a cable throttle body, what do you do? You make one, no other choice. Also, I installed a car oil pressure sending unit and attached the main vacuum line to the rear of the intake. After I swap the injector orings we are ready to do a final install on the intake. I've got the elbows on the catchcan in this pic, but until I see where the alternator is gonna end up I can't exact figure out the routing. Come on Huron Speed!!!!

Had to use an alternative set of fuel rail brackets and trim my spacers down by about 1/3 but everything seems to fit nice. Also, I ordered the FAST fat orings for the bottom of the injectors since everything LS2 and later have bigger injector holes then LS1 stuff. 146020COR is the part number. 3 bar MAP sensor is in place, and the stock wiring is gonna have to be extended.

The black fittings are -10 for the catchcan to valve covers, along with matching -10 black nylon lined hose, and the rest of the fittings are the elbows to come off the rails, then random vacuum line, an exhaust reducer (more on that later) and the Honda alternator. Yep my daily is down so I will be fixing it instead of doing race car stuff.

Super fast delivery....this is the PCV delete model, no vent tube. 92mm.

But that intake has no provisions for a cable throttle body, what do you do? You make one, no other choice. Also, I installed a car oil pressure sending unit and attached the main vacuum line to the rear of the intake. After I swap the injector orings we are ready to do a final install on the intake. I've got the elbows on the catchcan in this pic, but until I see where the alternator is gonna end up I can't exact figure out the routing. Come on Huron Speed!!!!