NoReverseYukon

Full Access Member

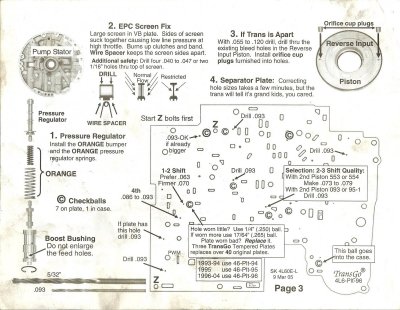

So, this code popped up a couple times over the last week. I read that it is commonly caused by wear in the PWM/TCC valve area on the valve body. I bought the TransGo SK 4L60E valve body repair kit. The instructions seem rather straight-forward, except for 1 thing that has me stumped. When it comes to drilling out/oversizing the holes in the separator plate - For example, if I am only installing a new PWM/TCC valve, should I only drill out the 2 holes that feed that valve, or should I drill out all the holes as the instructions show?

If anyone who installed this kit could chime in, I would greatly appreciate any advise.

Thanks

If anyone who installed this kit could chime in, I would greatly appreciate any advise.

Thanks