strutaeng

Full Access Member

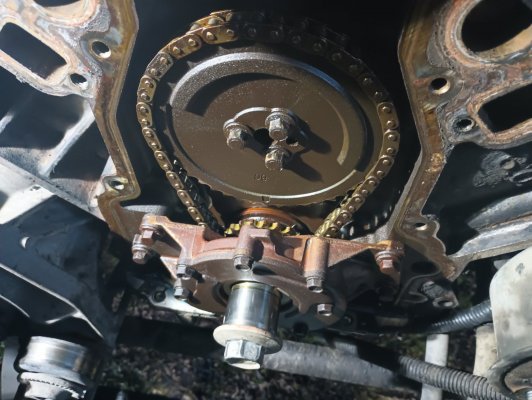

Hello. I'm doing a top end refresh on my 06 Suburban LQ4 (lifters, cam, refreshed heads, gaskets).

I removed the heads yesterday and found the rear most head bolts are pretty tight to the firewall. I happen to have just bought a 24" flex head ratchet, which was perfect for the job (admittedly , I was using a shallow socket and some extensions as that was I could find at the moment). But I'm kinda doubtful I'll be able to install the new head bolts in those 90 degrees sequence for the final requirement. I have a digital 24" torque wrench I'm planning on using for this.

Any tricks to doing that job? My buddy is suggesting ARP hardware. SMH.

I removed the heads yesterday and found the rear most head bolts are pretty tight to the firewall. I happen to have just bought a 24" flex head ratchet, which was perfect for the job (admittedly , I was using a shallow socket and some extensions as that was I could find at the moment). But I'm kinda doubtful I'll be able to install the new head bolts in those 90 degrees sequence for the final requirement. I have a digital 24" torque wrench I'm planning on using for this.

Any tricks to doing that job? My buddy is suggesting ARP hardware. SMH.