At this point, she was ready for a test drive.

No, she was not.

While the engine was running from the first start-up, I noticed the ABS and Traction Control system indicators illuminated on the instrument cluster. Hmmm...

After I shut the engine down to cool off, I went into the EBCM via the Tech 2, found no DTC's.

This morning, same thing. Engine running, ABS and Traction Control system indicators were illuminated. Same thing on the Tech 2, no DTC's. However, I looked closer. There were no DTC's because there were NO COMMS!!!

Oh no...what I did I screw up?

Using the Tech 2, I checked other modules: FSCM, ECM, TCM, BCM, etc...All had comms and were good. So the issue was with the EBCM.

OK, back in post #50, there was a little piece of plastic on top of one of the connectors for the underside of the underhood distribution box upper panel. Maybe I didn't get it blow off properly, and it was preventing all the pins from connecting. (Not likely, as I would expect more widespread electrical issues, but anyway).

I disconnected the battery (-) terminal and removed the distribution box upper panel again. Piece of plastic was not there. However, there was a tiny leaf fragment over one of the female pins. Surely that must be it. (Idiot...) I blew the leaf fragment off, blew everything else off, then reinstalled the upper panel. Reconnect the battery, restart the engine.

Same thing. Indicators on, no comms on the Tech 2.

OK...fall back on the basics. (BS. I cheated and went to the internet and had to remember the basics.) When a module has no comms, check powers and grounds. Looking at the wiring diagram, there are specific fuses in the underhood distribution box for the ABS/EBCM. EBCM shares grounds with other components. So, likely this is a power issue.

Using my power probe and the decal on the distribution box cover, I start checking all the ABS fuses. And quickly find an issue.

ABS fuse #9 is not there.

Say what? I have not had ABS and Traction Control issues before, so it HAD to be there before. What happened to the fuse? Only likely explanation was I pulled it, lost it, etc...

OK. Got a new 25A fuse, put it in slot #9. Retested.

All is well! No indicators, comms with the EBCM. I cleared a couple of DTC's from the battery being disconnected.

Yay me! (Idiot.)

I went for a short 8-mile test drive. Absolutely no issues.

I then went for a 60+ mile road trip to see family.

Escalade ran flawlessly. This thing flies!

I have been driving my wife's 2008 Chevrolet Equinox LTZ. 3.4L V-6, 5spd Aisin automatic transaxle. Not terrible, it is fast enough. But not very quick. I had forgotten how responsive my Escalade is.

And how wonderful the L94 sounds when I put my foot in the water pump.

Had absolutely no issues. Everything worked fine.

Sooo...on the drive, I had time to think. How in the heck did I lose the 25A ABS fuse? I only removed two fuses: #20 for the FUEL PUMP and #21 for the FSCM. Both were 25A. I removed them so the fuel pump wouldn't run while I had the key on for various reasons.

I had noted a discrepancy on the distribution box decal: there was a relay labeled FUEL PMP. However, there was no relay in my distribution box. Must be because my Escalade had an FSCM. Didn't need the fuel pump relay.

That kept turning over in my head on the drive. Then it clicked. If I didn't have a fuel pump relay, I probably didn't have a fuel pump fuse. When I thought I was pulling fuse #20, I actually pulled fuse #9. And when I reinstalled the fuse, I put it back in slot #20.

Once I got home, I removed the new fuse from slot #9. And swapped the fuse from slot #20 to slot #9.

Started the engine. It ran. And did not stop. And the MIL never illuminated. Meaning the fuel pump was running just fine.

So, Sherlock Holmes, what have we deduced? That I am an idiot.

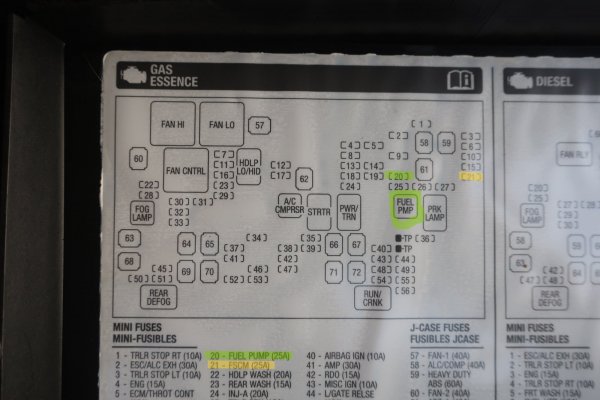

View attachment 417286

(In green) Fuel pump fuse #20 and fuel pump relay. (In yellow) FSCM fuse #21.

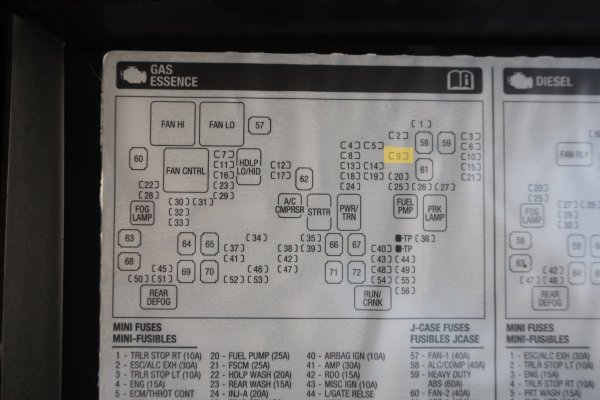

View attachment 417287

(In yellow) ABS fuse #9.

View attachment 417288

(In red) ABS fuse #9 (In green) Non-existent fuel pump fuse #20 and fuel pump relay.

With all this, other than checking the coolant level in the reservoir in the morning, I am now back to daily driving my Escalade.

It has been an interesting journey, as I once again have gone too far with simple maintenance.

I hope you all have enjoyed this thread and maybe learned something.

(I will say this, I have respect for people who post all the time like this on forums. It has taken me over 2.5 hours to make these last 7 posts...)