Hi all,

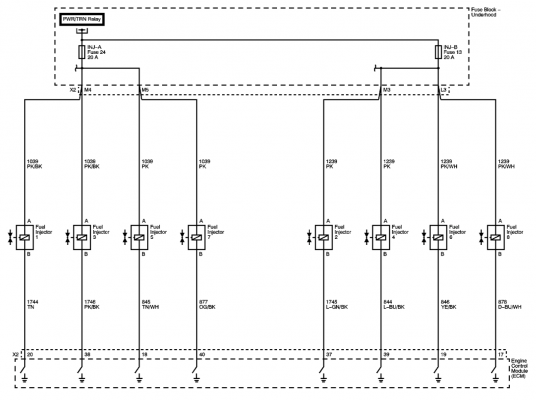

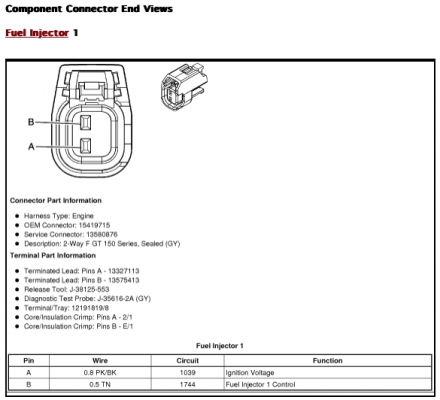

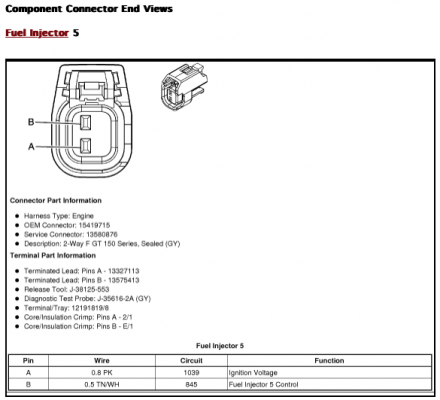

I have a 2013 Yukon Denali with the 6.2 engine. It has 115k miles on it. Lost a couple AFM lifters about two years ago, so parked it and just finished installing a BTR cam kit with AFM and VVT delete and a Black Bear tune. It starts and runs, but won’t fire the #1 or #5 injectors. I’ve checked everything I can think of…….compression 175-180 on all cylinders, swapped coils around, swapped injectors around, checked wiring harness, getting 12V to all injectors with ignition on and with engine running, checked continuity in all wiring to injectors, tried two different ECMs with and without tunes(no change), and checked all injectors with Noid light. Computer doesn’t seem to be telling #1 and #5 injectors to fire. #1 and #5 plugs are dry when I check them. Any help any of you can give would be greatly appreciated. No DTCs except “lean bank 1”. Thanks a bunch!

I have a 2013 Yukon Denali with the 6.2 engine. It has 115k miles on it. Lost a couple AFM lifters about two years ago, so parked it and just finished installing a BTR cam kit with AFM and VVT delete and a Black Bear tune. It starts and runs, but won’t fire the #1 or #5 injectors. I’ve checked everything I can think of…….compression 175-180 on all cylinders, swapped coils around, swapped injectors around, checked wiring harness, getting 12V to all injectors with ignition on and with engine running, checked continuity in all wiring to injectors, tried two different ECMs with and without tunes(no change), and checked all injectors with Noid light. Computer doesn’t seem to be telling #1 and #5 injectors to fire. #1 and #5 plugs are dry when I check them. Any help any of you can give would be greatly appreciated. No DTCs except “lean bank 1”. Thanks a bunch!