I'll add one more little tidbit into my adventure with the 6l80 rebuild.

I ran into an issue that is somewhat well documented with rebuilders.

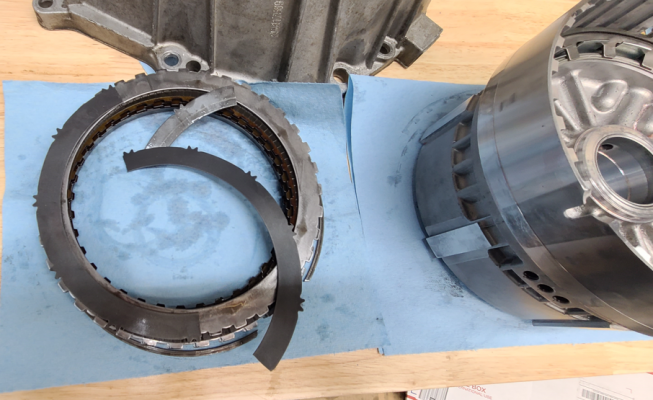

Apparently a batch of 6L90 1-2-3-4 drums went out with the 6L80 stickers.

That confused the hell out of me when trying to do endplay checks.

I couldn't get the stupid pump to seat!!

Then I remembered the note when watching the mass amount of youtube videos where one of the builders noted that as an "FYI" and to always compare the old part to the new one.

Sure enough, set the new drum next to the old one and I could see the height difference.

the 6l90 has an extra clutch plate or two, and the case is a little longer in that aspect.

In a way it sort of worked itself out,

I had issues with the selective snap rings, and the 2-6 clutch was out of spec.

And I couldn't source one that called out 2-6?!

and the instructions state that if the clutch clearances are wrong, then you assembled it incorrectly and to do it again.

I disassembled and reassembled several times, and it checked out!

So, I ended up using a snap ring from the 1-2-3-4 drum that fit perfectly (and with much better tension), that brought it right into the needed clearance spec.

doing a little mixing and matching I also got that 1-2-3-4 clutches nice and consistent with the rest of the build.

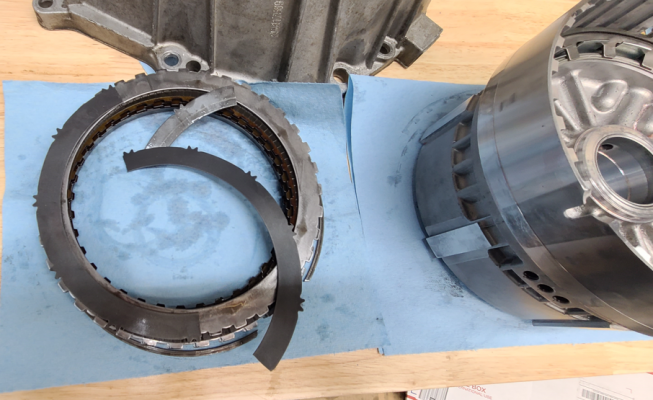

I also noted one youtube video where they ran into a broken wave plate in the 2-6, I had that in my transmission.

No symptoms that I noticed, but it looked like a ticking time bomb if those two broken pieces happened to bind up and fry the clutch.

Picture I posted in my build thread (

https://www.tahoeyukonforum.com/threads/just-fishings-09-tahoe-build-thread.125403/post-1666200 )