TrybalRage

Member

- Joined

- Jun 13, 2009

- Posts

- 94

- Reaction score

- 76

Alright fellas, new alternator on it's way. While I wait, I've pulled the main fuse box to check for corrosion (nope) and started pulling connectors on other modules to check them as well. Going to put a light coat of dielectric grease on them just for peace of mind, following this tsb.

I am a little concerned about a few codes that popped, still. The seat control going to ground (which according to alldata could also be just low voltage).

The fact that I cannot connect to the amp (is it disconnected? Malfunctioning? Replaced but never coded? Is the amp coded in these?) even when fully charged up.

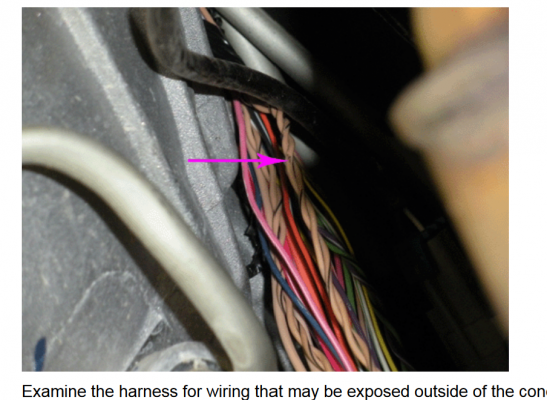

Checked high and low for any type of fleet tracking device per alldata. Looking for corroded/rubbed wire while I'm at it.

I am a little concerned about a few codes that popped, still. The seat control going to ground (which according to alldata could also be just low voltage).

The fact that I cannot connect to the amp (is it disconnected? Malfunctioning? Replaced but never coded? Is the amp coded in these?) even when fully charged up.

Checked high and low for any type of fleet tracking device per alldata. Looking for corroded/rubbed wire while I'm at it.