I posted a link to the bearing. What my buddy sent me was a screenshot of the Sloppy Mechanic's FB page. It's really not a complicated idea and, if you've ever seen a wheel bearing, you could use your imagination. Lemme see if I can dig up something.

*EDIT*

Here's the A-37 bearing:

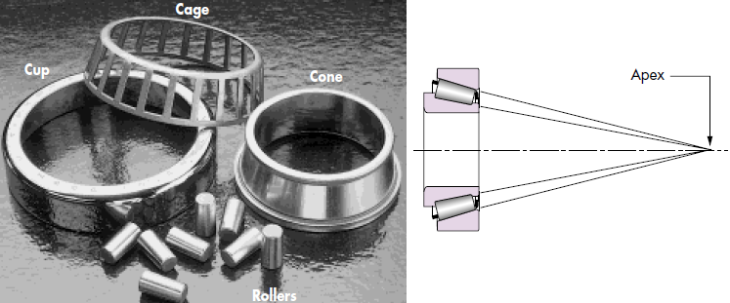

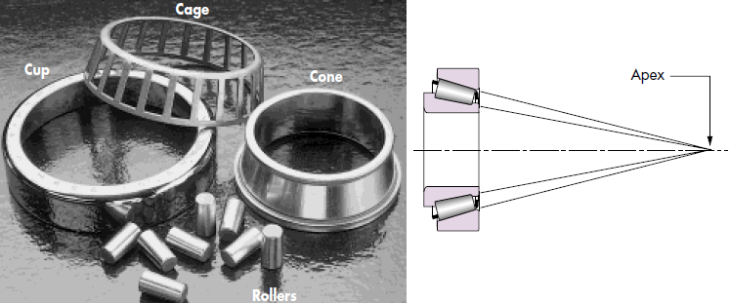

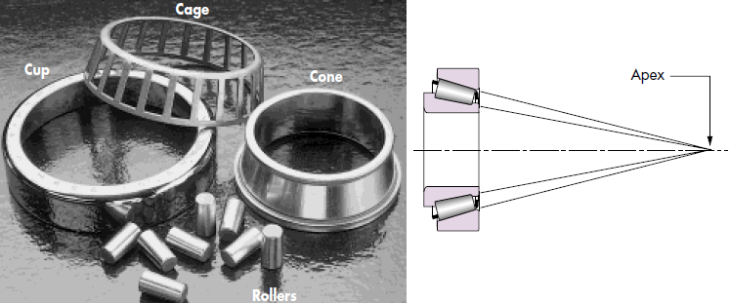

Here's what it'd look like disassembled:

The rollers have a slight taper to them. You use some dykes or a cut-off wheel on a grinder to cut the cage so all the rollers fall out. You may be able to bite it with a couple pairs of channel locks and bend it so the rollers fall out. You insert the smaller end of a roller "slug" into the hole of the AFM tower and tap it in until it's tight. The wider end of the roller is just big enough at some point to present an interference fit in the hole, so it must be right at 8mm in diameter.

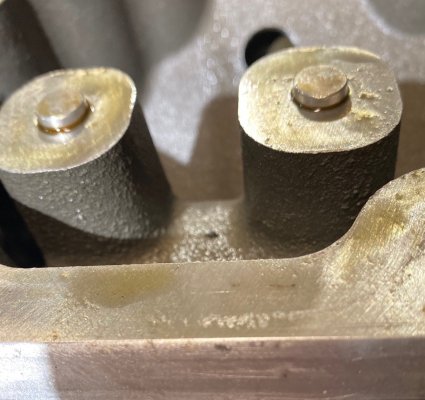

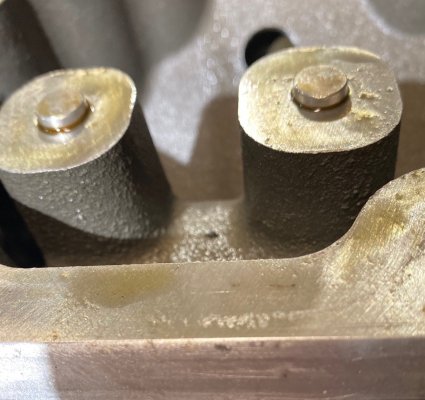

Here's some plugs installed. I don't know what kind or brand or it they're roller bearings, but it's all the same, super simple concept: