OilBurner2003

Full Access Member

- Joined

- Jul 24, 2022

- Posts

- 280

- Reaction score

- 170

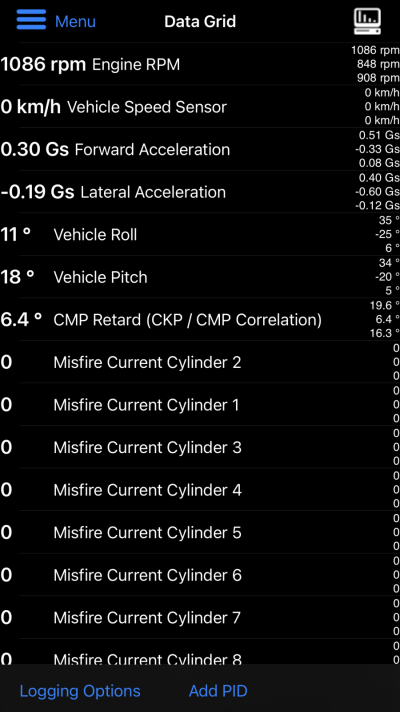

Roger, I’ll look at that too.Yep, but a quick check is to see if the dimple (below the pin) in the gear lines up with the paint mark and shows the rotor pointing to the “starting” spot before it drops in.

View attachment 386319