You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear U joint replacement

- Thread starter dkad260

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

Trey Hardy

8” fabtech icon coilovers uniballs 24x14on35/15.50

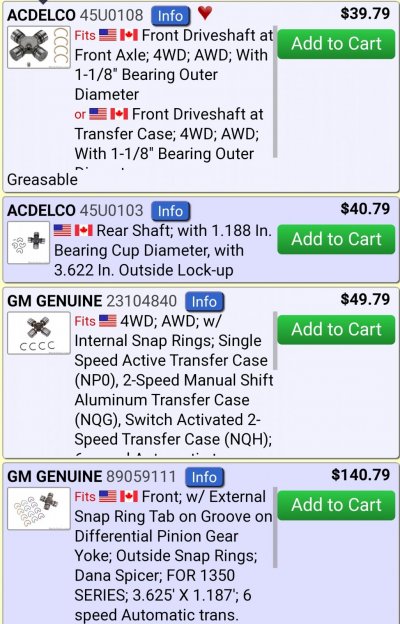

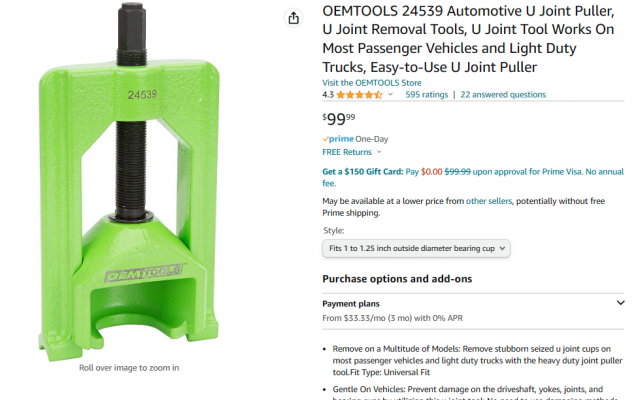

You can do it with a socket and a c clamp but it’s a biotch for sure. If you got a buddy or shop with a press it would be much easier to just unbolt it from the yoke pull it out and take it up to the shop.For the rear of a '12 Yukon, are these retained by a clip or are they epoxied?

They look to have clips but the front looks to have epoxy.

Curious if the rears need to be pressed or will a C-clamp work with a large socket.

Last time I tried the c clamp idea it made a 30-45 min job turn into a 4 hour job and had to use the torch to get it broke free granted this was in my 93 Silverado and it had the original u joints.

I got a new set for my 07 Tahoe but the factory ones some how are still holding up good so I threw them in my trunk just incase one were to give out while I was on the road.

If you see clips, then that's the way in/out. I'm not sure when the epoxy thing ended, but if memory serves me right almost all the new stuff with aluminum shafts have clips.For the rear of a '12 Yukon, are these retained by a clip or are they epoxied?

They look to have clips but the front looks to have epoxy.

Curious if the rears need to be pressed or will a C-clamp work with a large socket.

If you have a good vice, you can let it hold the yoke loosely (more like a contained rest of sorts). Use a pic to clean up the ring groove, emery cloth the yoke if it's corroded, then use a small amount of oil on your finger to lube the hole.

Once you get the u-joint in the yoke, you can slip the caps in until they are tight by hand. Hold the driveshaft so it's centered and engaging both caps (this keeps the needle bearings in their place). Then tap lightly with a hammer to seat the caps in.

Get one in fully and install the snap ring. Then repeat the other side. If it's too tight after setting it and putting the clip in, use the vice to support the other 2 caps and tap lightly at he yoke weld to back the caps out against the clips. Done this for years. It takes some practice, but works slick.

Joseph Garcia

Supporting Member

- Joined

- Aug 2, 2018

- Posts

- 6,485

- Reaction score

- 8,479

^^^x2^^^ Just be VERY careful not to upset the bearings in the cap while you slip it into the yoke. I once had a bearing drop down into the cap once, because I was not careful enough.

Learned these steps years ago and works great. Have to have a steady hand and attention to detail but it works.If you see clips, then that's the way in/out. I'm not sure when the epoxy thing ended, but if memory serves me right almost all the new stuff with aluminum shafts have clips.

If you have a good vice, you can let it hold the yoke loosely (more like a contained rest of sorts). Use a pic to clean up the ring groove, emery cloth the yoke if it's corroded, then use a small amount of oil on your finger to lube the hole.

Once you get the u-joint in the yoke, you can slip the caps in until they are tight by hand. Hold the driveshaft so it's centered and engaging both caps (this keeps the needle bearings in their place). Then tap lightly with a hammer to seat the caps in.

Get one in fully and install the snap ring. Then repeat the other side. If it's too tight after setting it and putting the clip in, use the vice to support the other 2 caps and tap lightly at he yoke weld to back the caps out against the clips. Done this for years. It takes some practice, but works slick.

Just Fishing

Can't fix stupid

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 1

- Views

- 689

- Replies

- 10

- Views

- 2K

- Replies

- 64

- Views

- 5K

- Replies

- 46

- Views

- 3K