iamdub

Full Access Member

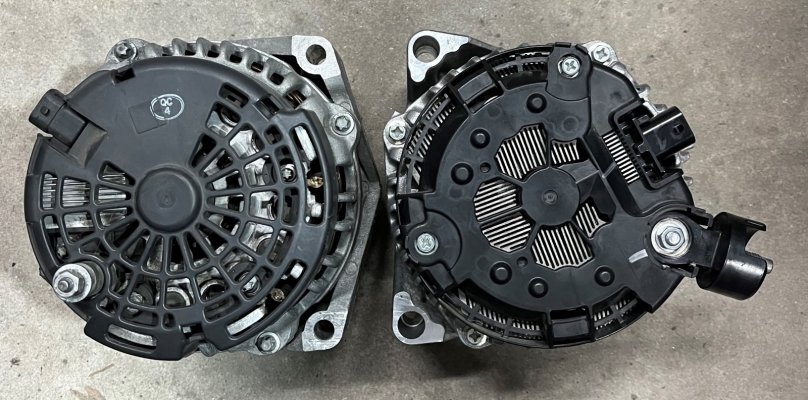

Just bought another alternator- #13534128. Seller had pics from all angles. Was listed at $135.96 but had a 20% discount code bringing it to $108.77. Add $10.28 in tax and I'm in it for $119.05. This one has 21,712 miles. New enough for me. No clutch.

I dug through so many listings and most either didn't specify what engine the wrecked truck had or they were the 2.7L, verified by the underhood pics. Yet, they had the alternators listed as fitting the V8s. No pics or part numbers for the actual alternators for which those listings were created. Bunch of BS.

I dug through so many listings and most either didn't specify what engine the wrecked truck had or they were the 2.7L, verified by the underhood pics. Yet, they had the alternators listed as fitting the V8s. No pics or part numbers for the actual alternators for which those listings were created. Bunch of BS.