You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knock sensors

- Thread starter 992dr

- Start date

Disclaimer: Links on this page pointing to Amazon, eBay and other sites may include affiliate code. If you click them and make a purchase, we may earn a small commission.

If both knock sensors are throwing a code, can they cause a reduction in engine power? I have an 05 Tahoe with a 5.3 that is struggling to get out of its own way right now, I’ve deleted cats and changed plugs, replaced the purge flow solenoid as well. With none of these helping. It’s throwing so many codes I’m not sure where to go next.

Deleting the cats will do that

The wiring harness to the sensors can also be replaced seprately, could it be a wiring issue? Wire nick,cut etc.

After changing them Sunday, the light stayed on for one day then cleared again. It has not come back on since.

I'll have to look around and see if there is a nick or cut somewhere. I'm all about preventative maintenance hah.

Deleting the cats will do that

I haven't done my exhaust yet. It's all stock.

Matthew Jeschke

Full Access Member

I have same problem but brought on by my own stupidity. I hate to invest too much in this 5.3 motor as I plan to build a 6.0 just haven't found the block yet. I power washed behind my water pump when I replaced it. Then put everything back together. I think some of the water got under the intake and into the knock sensor (my guess). Now I'm throwing P0332 code

I'm not sure if P0332 indicates I wrecked one or both of the knock sensors under the intake. And if I can get by with one bad knock sensor. Truck runs fine otherwise.

I'm not sure if P0332 indicates I wrecked one or both of the knock sensors under the intake. And if I can get by with one bad knock sensor. Truck runs fine otherwise.

Matthew Jeschke

Full Access Member

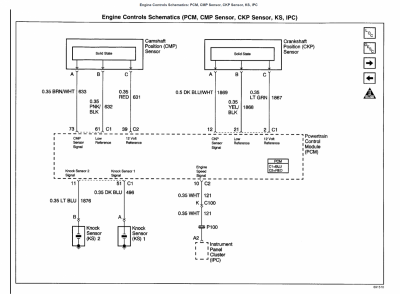

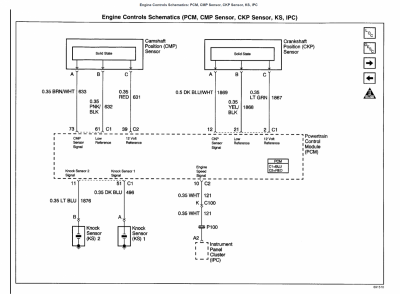

I'm going to save a few notes in here in case anybody else comes across this thread.

P0327 - Front knock sensor closest throttle body

P0332 - Rear knock sensor closets bell housing

Nominal sensor has 93k to 107k Ohms resistance (can test through connector to chassis ground / engine block).

Nominal output is AC 400mV. Tap on engine block with wrench and see if you get signal on DMM.

Wiring harness copied below:

P0327 - Front knock sensor closest throttle body

P0332 - Rear knock sensor closets bell housing

Nominal sensor has 93k to 107k Ohms resistance (can test through connector to chassis ground / engine block).

Nominal output is AC 400mV. Tap on engine block with wrench and see if you get signal on DMM.

Wiring harness copied below:

Last edited:

I have same problem but brought on by my own stupidity. I hate to invest too much in this 5.3 motor as I plan to build a 6.0 just haven't found the block yet. I power washed behind my water pump when I replaced it. Then put everything back together. I think some of the water got under the intake and into the knock sensor (my guess). Now I'm throwing P0332 code

I'm not sure if P0332 indicates I wrecked one or both of the knock sensors under the intake. And if I can get by with one bad knock sensor. Truck runs fine otherwise.

Gen IV knock sensors are not under the intake, they are located on the bottom sides of the block.

iamdub

Full Access Member

I have same problem but brought on by my own stupidity. I hate to invest too much in this 5.3 motor as I plan to build a 6.0 just haven't found the block yet. I power washed behind my water pump when I replaced it. Then put everything back together. I think some of the water got under the intake and into the knock sensor (my guess). Now I'm throwing P0332 code

I'm not sure if P0332 indicates I wrecked one or both of the knock sensors under the intake. And if I can get by with one bad knock sensor. Truck runs fine otherwise.

Just replace both as well as the harness since you'll already have the manifold off. When you build the 6.0, swap the sensors and harness over to it. Be sure to blow and vacuum out the holes before you remove the sensor(s) so no debris falls in. Apply a moderate layer of RTV to the underside of the flaps on the harness so they seal to the valley cover and keep water out.

Matthew Jeschke

Full Access Member

Ah I didn't realize your post was for gen 4... I have a gen 3.Gen IV knock sensors are not under the intake, they are located on the bottom sides of the block.

Sent from my SM-A505U using Tapatalk

Ah I didn't realize your post was for gen 4... I have a gen 3.

Sent from my SM-A505U using Tapatalk

Ooooh gotcha

, I'd do exactly what iamdub suggested

, I'd do exactly what iamdub suggested

Matthew Jeschke

Full Access Member

Tore it down, fun project... I'm a glutton for punishment haha Just don't like the $50 I'm spending on a motor I plan to get rid of. Got two new knock sensors, harness, and intake gasket. I must say, this Gen 3 design is BAD, at least they could have made a better seal for the sensor / harness. It was laughable. Certainly had been water accumulating in there for a long time. It looked like I raised a cannon from a sunken ship haha. I measured resistance and was basically an open. The second sensor looks great. The harness still made a connection but has a bunch of resistance in it so needs junked. Thanks everybody for the help. I'll probably RTV the seal in as I've seen other people do when I put it back together.