Matthew Jeschke

Full Access Member

My front AC only seems to cool when I'm going down the highway. The rear blows icy cold all the time. A little over a year ago I went through the system as desiccant bag broke and plugged up the expansion valve and orifice tube:

- Cleaned all the lines with ether / starting fluid and blew out with compressed air.

- Replaced all the o-rings

- Replaced expansion valve in rear evap and orifice tube in front.

- Replaced dryer accumulator

- Put new oil in and charged system.

Worked like a champ until a little while ago. Front air doesn't really cool until moving down highway. Rear air is nice and cold while not moving down road. I've done a little diagnostic work.

- System off / Static pressure in lines is 100 PSI at 85F ambient (within spec).

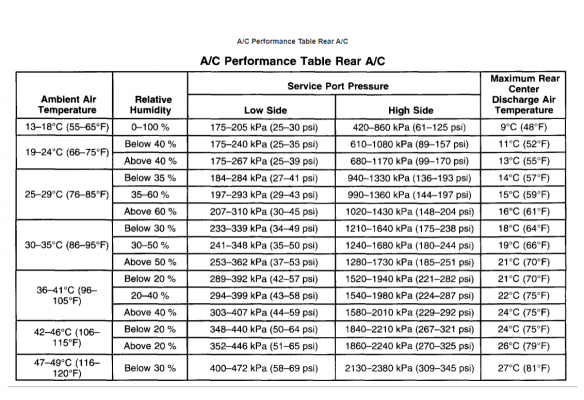

- System on 85F ambient, 40 PSI low side 190 PSI high side (cannot find spec in all data DIY for this)

- Line next to condenser is HOT and line close to firewall is BEER CAN COLD. Seems good.

- Not sure if normal AC clutch runs for a while, then turns off and cycles back on.

- I forced blend door on front air handler to cold air (actuator has an issue so fixed to cold and unpluged).

I'm trying to find spec on splits high to low side pressure. I have All Data DIY but cannot find that spec or table. Maybe there's a generic r134a table?

Any other ideas as to my issue would be greatly appreciated.

- Cleaned all the lines with ether / starting fluid and blew out with compressed air.

- Replaced all the o-rings

- Replaced expansion valve in rear evap and orifice tube in front.

- Replaced dryer accumulator

- Put new oil in and charged system.

Worked like a champ until a little while ago. Front air doesn't really cool until moving down highway. Rear air is nice and cold while not moving down road. I've done a little diagnostic work.

- System off / Static pressure in lines is 100 PSI at 85F ambient (within spec).

- System on 85F ambient, 40 PSI low side 190 PSI high side (cannot find spec in all data DIY for this)

- Line next to condenser is HOT and line close to firewall is BEER CAN COLD. Seems good.

- Not sure if normal AC clutch runs for a while, then turns off and cycles back on.

- I forced blend door on front air handler to cold air (actuator has an issue so fixed to cold and unpluged).

I'm trying to find spec on splits high to low side pressure. I have All Data DIY but cannot find that spec or table. Maybe there's a generic r134a table?

Any other ideas as to my issue would be greatly appreciated.