mals

Full Access Member

Hello all -

I purchased my 2005 6.0L AWD Yukon Denali in June 2016 with 155K on the odometer. I’ve been active on and off here on the forum over the past year and a half, but thought it was time to put all the work I’ve done in one place. Mostly for my own benefit, but also hopeful for the use of others that are planning to tackle similar projects.

This vehicle was primarily purchased as a tow vehicle for our travel trailer. I’ve had Silverados as work trucks for the past 15 year, so when I was looking at full sized tow vehicles the Yukon felt familiar and comfortable. I was planning on just getting a beater of a Tahoe or Yukon, but I happened across a Yukon Denali that was in decent shape, but needed a little TLC, and was priced to sell. I knew it had some issues, but they all seemed like things I could work on myself. With the help of this forum, and the countless how-to videos on YouTube, it’s been a fun project.

Here are the items I've successfully tackled so far:

-mals

I purchased my 2005 6.0L AWD Yukon Denali in June 2016 with 155K on the odometer. I’ve been active on and off here on the forum over the past year and a half, but thought it was time to put all the work I’ve done in one place. Mostly for my own benefit, but also hopeful for the use of others that are planning to tackle similar projects.

This vehicle was primarily purchased as a tow vehicle for our travel trailer. I’ve had Silverados as work trucks for the past 15 year, so when I was looking at full sized tow vehicles the Yukon felt familiar and comfortable. I was planning on just getting a beater of a Tahoe or Yukon, but I happened across a Yukon Denali that was in decent shape, but needed a little TLC, and was priced to sell. I knew it had some issues, but they all seemed like things I could work on myself. With the help of this forum, and the countless how-to videos on YouTube, it’s been a fun project.

Here are the items I've successfully tackled so far:

- Exhaust Manifold Gaskets (and extract 4 broken manifold bolts)

- Engine Coolant Temp Sensor (Snapped while working on exhaust manifold)

- Replaced Spark Plugs (Since I pulled the old ones working on the manifold)

- Replaced the Oil Pressure Sending Unit

- Replaced the Passenger Side Air Blend Door Actuator

- Replaced Exhaust Hanger Isolators

- Installed new 4300k HID Low Beams with 55W Ballasts

- Replaced the 8 mini-bulbs in the Steering Wheel Controls

- Replaced the 11 mini-bulbs in the HVAC Control Unit

- Replaced the mini-bulbs and stepper motors in the Gauge Cluster

- Reflowed the solder on the surface mount resistors to restore dim PRND321 display

- Installed NNBS Yukon 5307 Aluminum 20" Rims w/ four new NBS TPMS sensors

- Full Sized Matched Spare Made Using a 20" Rim from a 2009 Nissan Titan

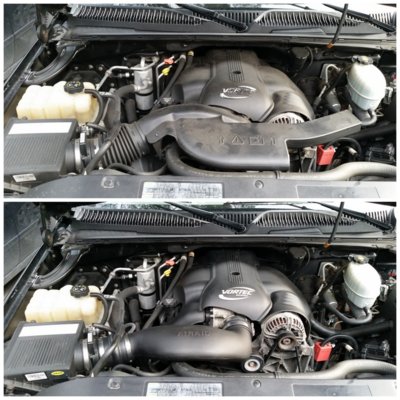

- Installed AirAid Modular Intake Tube

- Blacked Out Denali Mesh Grille Inset

- Replaced Yellowed Headlights w/ NOS OEM Housings

- Oil & Filter Change – Pennzoil Platnum HM Synthetic & Mobil 1 M-107A (160K)

- Serviced Transfer Case – Amsoil Signature Series Synthetic ATF (160K)

- Serviced Rear Differential – Amsoil Severe Gear Synthetic 75W-90, Lube Locker Gasket, & Replacement Cover (160K)

- Serviced Front Differential – Amsoil Severe Gear Synthetic 75W-90 (160K)

- Replaced Pitman Arm, Idler Arm, and Idler Bracket (161K)

- Replace Turn Signal Flasher Module (161K)

- Replace A/C Evaporator Core Case GM #88891577 & Actuator GM #52402599 (162K)

- Upgraded the Front Brakes to NNBS Equipment (Calipers / Rotors / Pads)

- Replaced Rear Brakes (Calipers / Rotors / Pads / Parking Shoes)

- Replaced All Flex Brake Lines with Stainless Lines (Goodridge 6-line G-Stop)

- Replaced Front & Rear Bump Stops

- Replaced Front Ride Level Sensor

- Service Transmission – Filter & Full Volume Replacement using Amsoil Signature Series Synthetic ATF

- Black Bear AutoCal Tune (Used AutoCal Purchased / Waiting to Purchase Tune)

- Repair / Replace Damaged Hood

-mals

Last edited: