PG01

Supporting Member

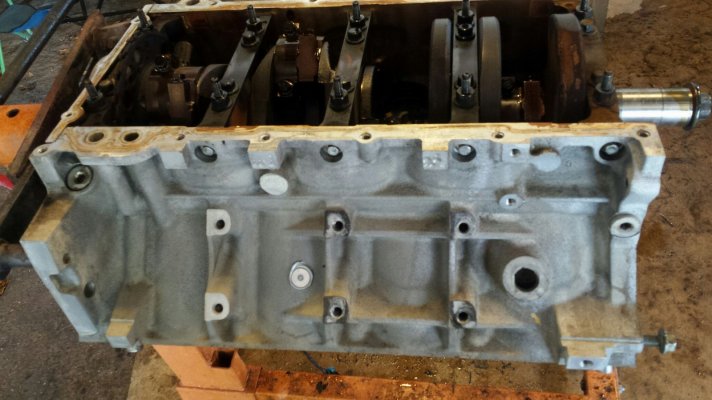

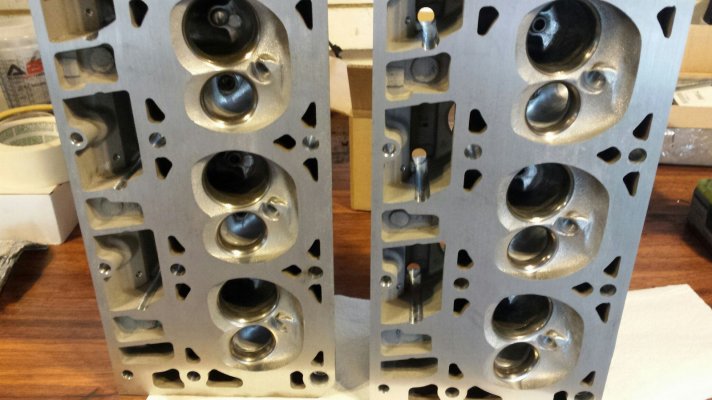

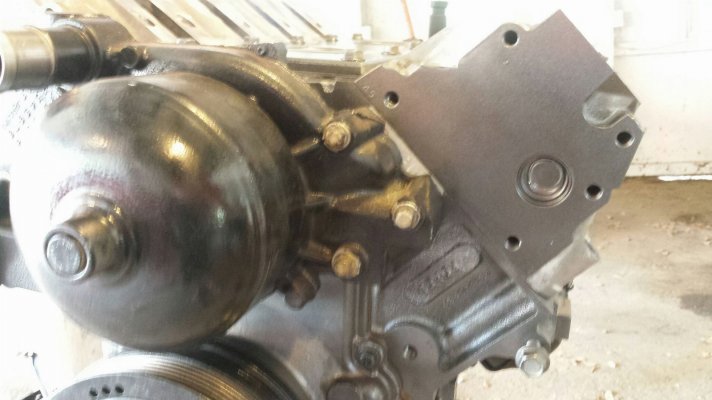

Sorry man, but sounds like itll be badass tho...Well this is a depressing update with a happy ending. Go back to the oil pressure issues. I figured out the black junk was from the rocker arms, it was flaking off, so that was accounted for being in the filter. The car was running good and AFR wasnt bad so we went on a drive, after a couple of quick reflashes she went into boost for the first time. Holy ****** of God. The pull at 7 psi on the wastegate spring is retarded. I am officially in love with boost. After experiencing this glory one friggen time, the oil pressure tanked again. Luckily we were close to home and I limped it there, and swapped filters again. All back to normal. So I go on about tuning some more and even gave a couple test rides to friends (no traction from a roll), and on my final drive of yesterday it happened.......we buzzed the neighbors standing outside with the turbo whirl and the BOV pop, made a pull and it was there.......a rod knock. After examining all top end components i crawled under and pulled the filter and it was clogged with metal debris. I believe the previous two had been also I just saw it to be dark and assumed it was sludge. So we are gonna make the best of it, and go back with an aluminum block this go round to shave some weight. I know this motor didnt run long but damn was it glorious when it did.

To note, the brakes are growing on me some, the converter from circle D feels perfect, I can build boost quickly, I was even able to footbrake to 3k on a dusty blacktop road so that has a lot of potential and my trans cooling is not adequate. Ive got a sister cooler and fan on the way and will be doubling cooling capacity while maintaining the rearmount cooler setup. Also, the BOV with the lightweight spring was staying open at idle, and with the heavy spring would not open at all. This is what i did to the heavy spring to make it work correctly.

Side info, I was pretty disgusted with the situation so I made the best of it and put some new cabinets and microwave in the Camaro's corner of the garage. I may run a dedicated outlet for the microwave but for now just ran a cord to it. This is a hangout spot for us LS guys to hatch our devious racecar plans where the womenfolk cant find about it! Pretty nice cabinets for being store bought home depot thingys.

New motor to come grrrrrrr.